If this steel is quenched rapidly from 1000 C to 500 C held

If this steel is quenched rapidly from 1000 C to 500 C, held for 1 minute, then cooled to room temperature, describe the microstructure which will result and explain the mechanism of formation.

Solution

Answer :

The microstructure is Martensite.

Mechanism of formation :

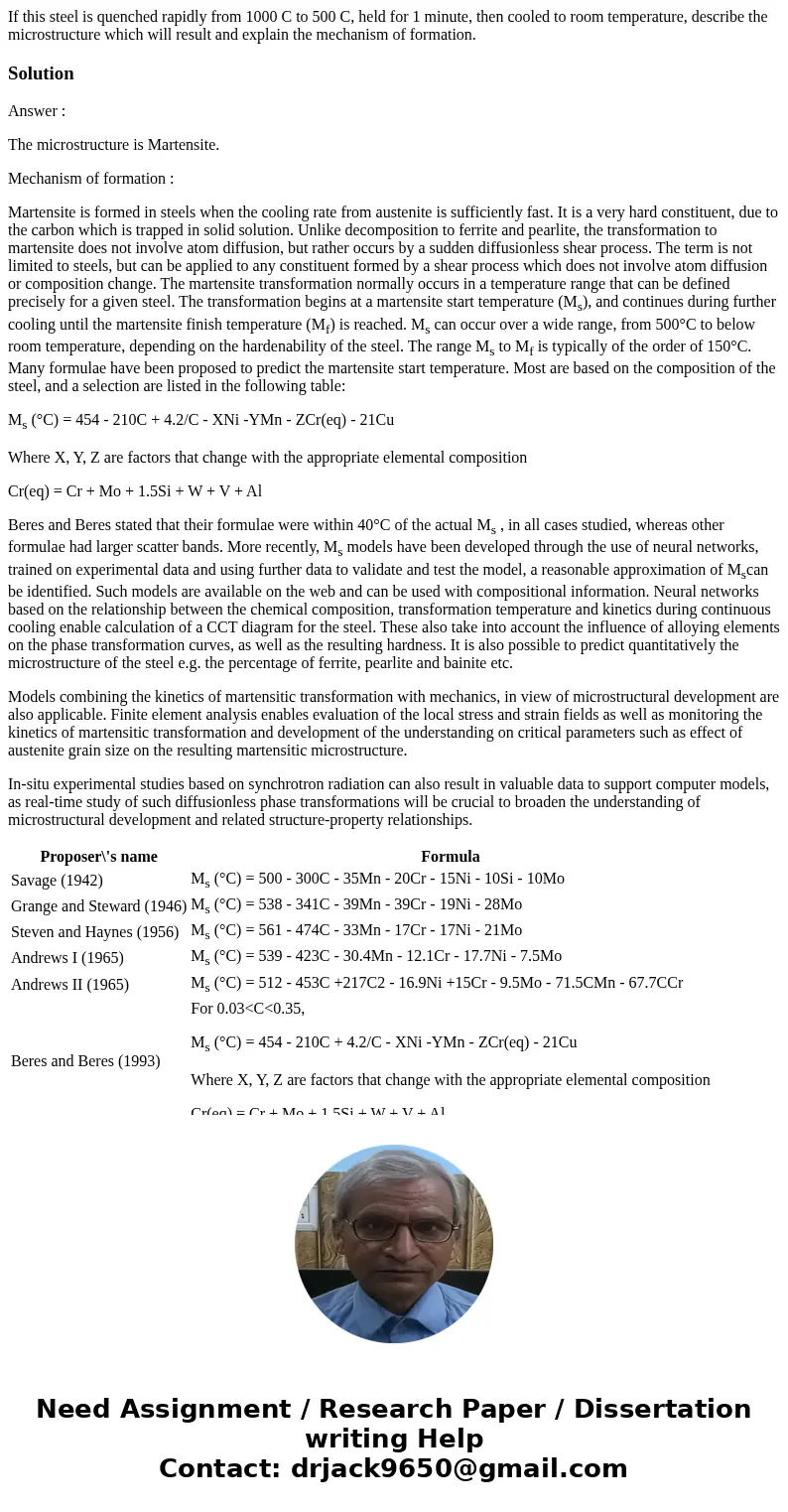

Martensite is formed in steels when the cooling rate from austenite is sufficiently fast. It is a very hard constituent, due to the carbon which is trapped in solid solution. Unlike decomposition to ferrite and pearlite, the transformation to martensite does not involve atom diffusion, but rather occurs by a sudden diffusionless shear process. The term is not limited to steels, but can be applied to any constituent formed by a shear process which does not involve atom diffusion or composition change. The martensite transformation normally occurs in a temperature range that can be defined precisely for a given steel. The transformation begins at a martensite start temperature (Ms), and continues during further cooling until the martensite finish temperature (Mf) is reached. Ms can occur over a wide range, from 500°C to below room temperature, depending on the hardenability of the steel. The range Ms to Mf is typically of the order of 150°C. Many formulae have been proposed to predict the martensite start temperature. Most are based on the composition of the steel, and a selection are listed in the following table:

Ms (°C) = 454 - 210C + 4.2/C - XNi -YMn - ZCr(eq) - 21Cu

Where X, Y, Z are factors that change with the appropriate elemental composition

Cr(eq) = Cr + Mo + 1.5Si + W + V + Al

Beres and Beres stated that their formulae were within 40°C of the actual Ms , in all cases studied, whereas other formulae had larger scatter bands. More recently, Ms models have been developed through the use of neural networks, trained on experimental data and using further data to validate and test the model, a reasonable approximation of Mscan be identified. Such models are available on the web and can be used with compositional information. Neural networks based on the relationship between the chemical composition, transformation temperature and kinetics during continuous cooling enable calculation of a CCT diagram for the steel. These also take into account the influence of alloying elements on the phase transformation curves, as well as the resulting hardness. It is also possible to predict quantitatively the microstructure of the steel e.g. the percentage of ferrite, pearlite and bainite etc.

Models combining the kinetics of martensitic transformation with mechanics, in view of microstructural development are also applicable. Finite element analysis enables evaluation of the local stress and strain fields as well as monitoring the kinetics of martensitic transformation and development of the understanding on critical parameters such as effect of austenite grain size on the resulting martensitic microstructure.

In-situ experimental studies based on synchrotron radiation can also result in valuable data to support computer models, as real-time study of such diffusionless phase transformations will be crucial to broaden the understanding of microstructural development and related structure-property relationships.

| Proposer\'s name | Formula |

|---|---|

| Savage (1942) | Ms (°C) = 500 - 300C - 35Mn - 20Cr - 15Ni - 10Si - 10Mo |

| Grange and Steward (1946) | Ms (°C) = 538 - 341C - 39Mn - 39Cr - 19Ni - 28Mo |

| Steven and Haynes (1956) | Ms (°C) = 561 - 474C - 33Mn - 17Cr - 17Ni - 21Mo |

| Andrews I (1965) | Ms (°C) = 539 - 423C - 30.4Mn - 12.1Cr - 17.7Ni - 7.5Mo |

| Andrews II (1965) | Ms (°C) = 512 - 453C +217C2 - 16.9Ni +15Cr - 9.5Mo - 71.5CMn - 67.7CCr |

| Beres and Beres (1993) | For 0.03<C<0.35, Ms (°C) = 454 - 210C + 4.2/C - XNi -YMn - ZCr(eq) - 21Cu Where X, Y, Z are factors that change with the appropriate elemental composition Cr(eq) = Cr + Mo + 1.5Si + W + V + Al |

Homework Sourse

Homework Sourse