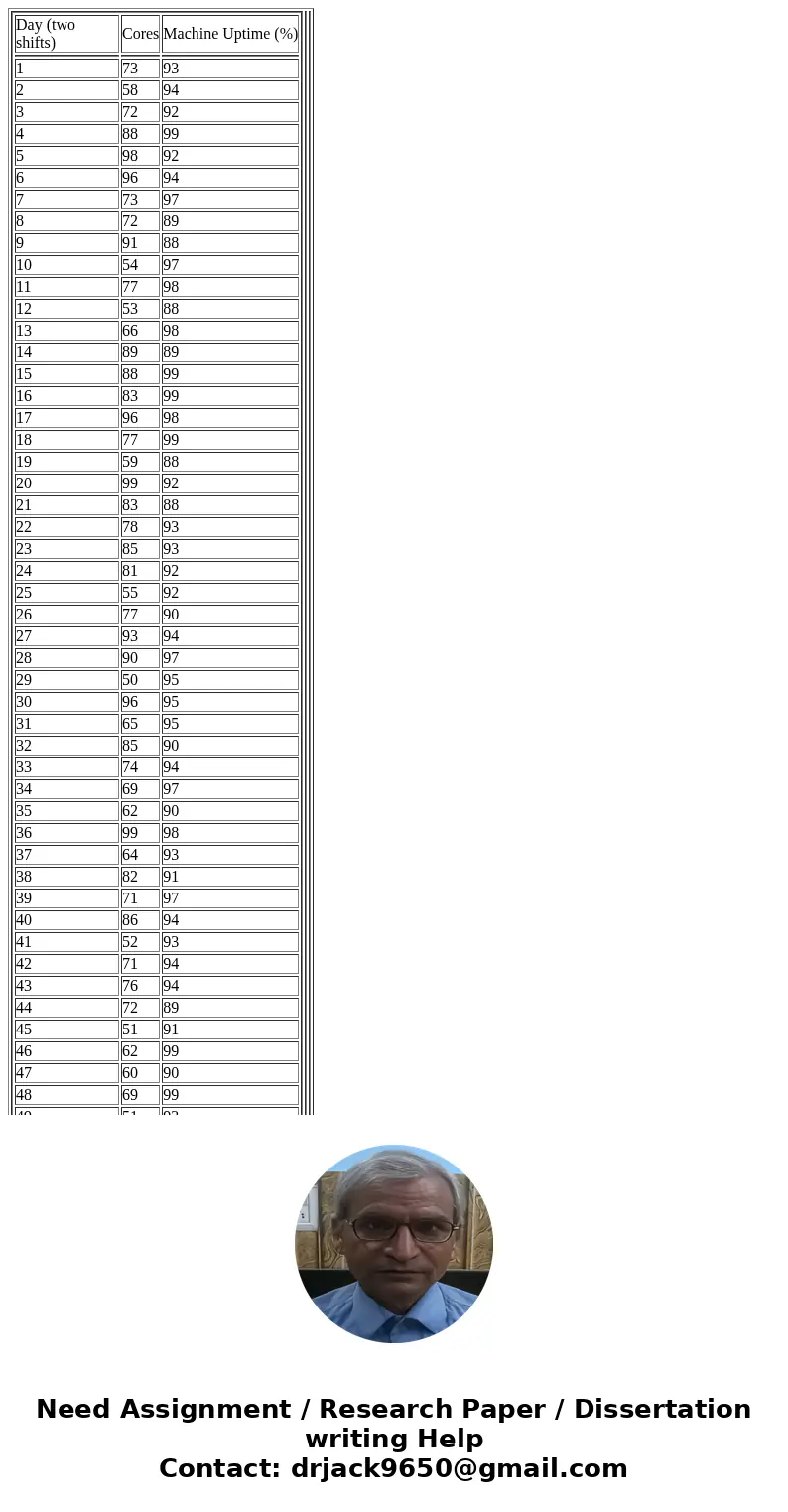

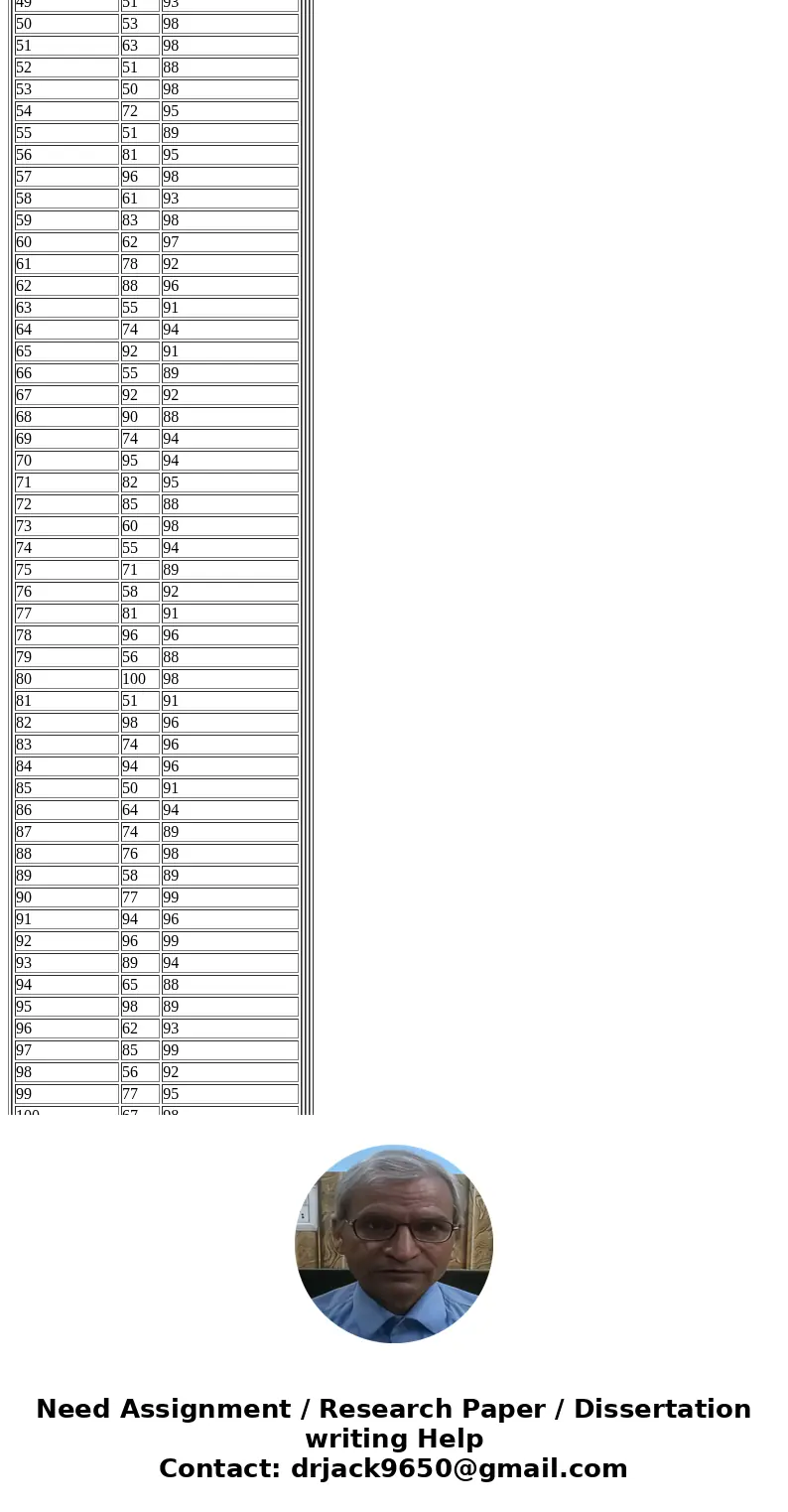

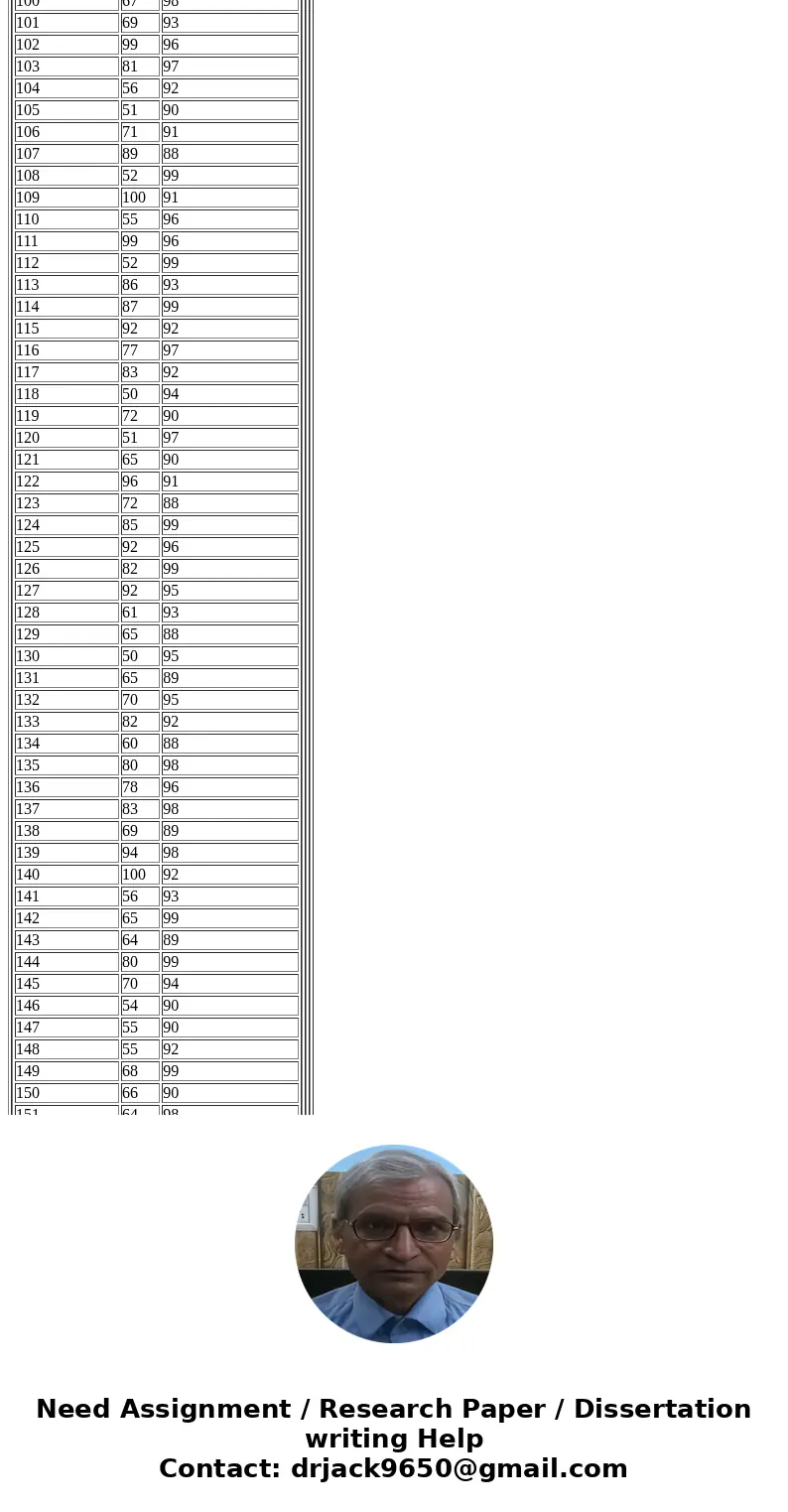

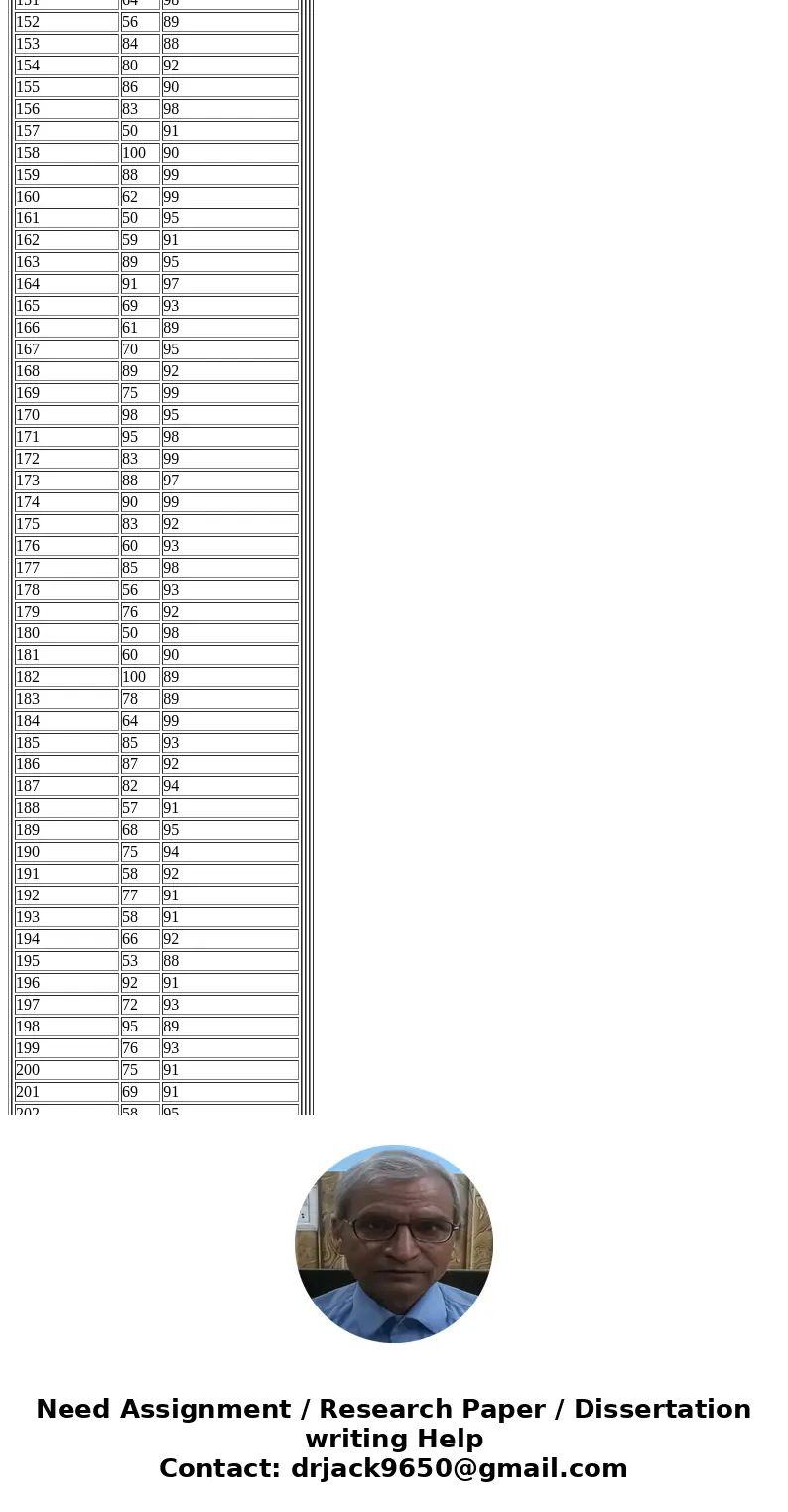

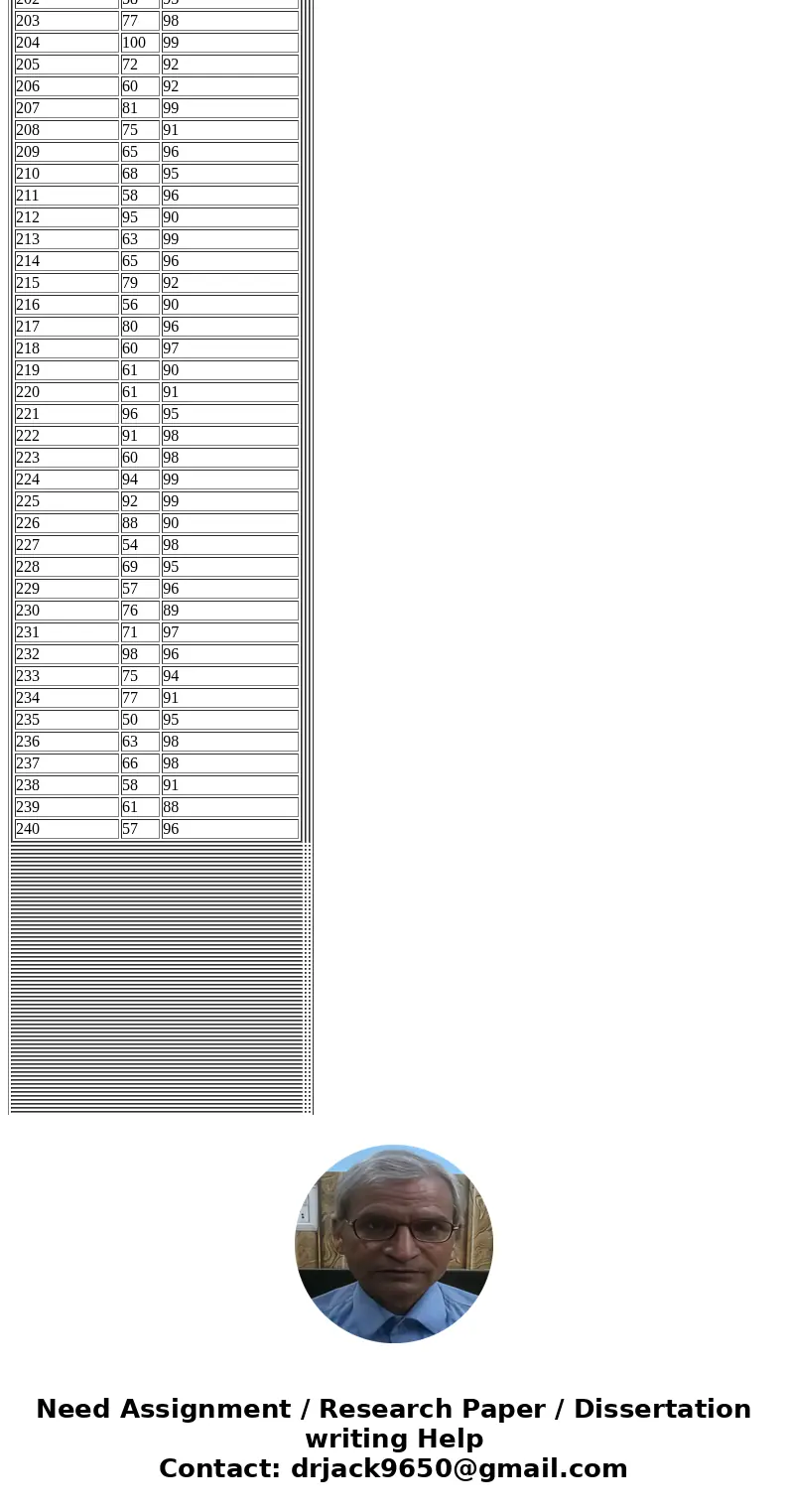

| Day (two shifts) | Cores | Machine Uptime (%) | | | | | 1 | 73 | 93 | | 2 | 58 | 94 | | 3 | 72 | 92 | | 4 | 88 | 99 | | 5 | 98 | 92 | | 6 | 96 | 94 | | 7 | 73 | 97 | | 8 | 72 | 89 | | 9 | 91 | 88 | | 10 | 54 | 97 | | 11 | 77 | 98 | | 12 | 53 | 88 | | 13 | 66 | 98 | | 14 | 89 | 89 | | 15 | 88 | 99 | | 16 | 83 | 99 | | 17 | 96 | 98 | | 18 | 77 | 99 | | 19 | 59 | 88 | | 20 | 99 | 92 | | 21 | 83 | 88 | | 22 | 78 | 93 | | 23 | 85 | 93 | | 24 | 81 | 92 | | 25 | 55 | 92 | | 26 | 77 | 90 | | 27 | 93 | 94 | | 28 | 90 | 97 | | 29 | 50 | 95 | | 30 | 96 | 95 | | 31 | 65 | 95 | | 32 | 85 | 90 | | 33 | 74 | 94 | | 34 | 69 | 97 | | 35 | 62 | 90 | | 36 | 99 | 98 | | 37 | 64 | 93 | | 38 | 82 | 91 | | 39 | 71 | 97 | | 40 | 86 | 94 | | 41 | 52 | 93 | | 42 | 71 | 94 | | 43 | 76 | 94 | | 44 | 72 | 89 | | 45 | 51 | 91 | | 46 | 62 | 99 | | 47 | 60 | 90 | | 48 | 69 | 99 | | 49 | 51 | 93 | | 50 | 53 | 98 | | 51 | 63 | 98 | | 52 | 51 | 88 | | 53 | 50 | 98 | | 54 | 72 | 95 | | 55 | 51 | 89 | | 56 | 81 | 95 | | 57 | 96 | 98 | | 58 | 61 | 93 | | 59 | 83 | 98 | | 60 | 62 | 97 | | 61 | 78 | 92 | | 62 | 88 | 96 | | 63 | 55 | 91 | | 64 | 74 | 94 | | 65 | 92 | 91 | | 66 | 55 | 89 | | 67 | 92 | 92 | | 68 | 90 | 88 | | 69 | 74 | 94 | | 70 | 95 | 94 | | 71 | 82 | 95 | | 72 | 85 | 88 | | 73 | 60 | 98 | | 74 | 55 | 94 | | 75 | 71 | 89 | | 76 | 58 | 92 | | 77 | 81 | 91 | | 78 | 96 | 96 | | 79 | 56 | 88 | | 80 | 100 | 98 | | 81 | 51 | 91 | | 82 | 98 | 96 | | 83 | 74 | 96 | | 84 | 94 | 96 | | 85 | 50 | 91 | | 86 | 64 | 94 | | 87 | 74 | 89 | | 88 | 76 | 98 | | 89 | 58 | 89 | | 90 | 77 | 99 | | 91 | 94 | 96 | | 92 | 96 | 99 | | 93 | 89 | 94 | | 94 | 65 | 88 | | 95 | 98 | 89 | | 96 | 62 | 93 | | 97 | 85 | 99 | | 98 | 56 | 92 | | 99 | 77 | 95 | | 100 | 67 | 98 | | 101 | 69 | 93 | | 102 | 99 | 96 | | 103 | 81 | 97 | | 104 | 56 | 92 | | 105 | 51 | 90 | | 106 | 71 | 91 | | 107 | 89 | 88 | | 108 | 52 | 99 | | 109 | 100 | 91 | | 110 | 55 | 96 | | 111 | 99 | 96 | | 112 | 52 | 99 | | 113 | 86 | 93 | | 114 | 87 | 99 | | 115 | 92 | 92 | | 116 | 77 | 97 | | 117 | 83 | 92 | | 118 | 50 | 94 | | 119 | 72 | 90 | | 120 | 51 | 97 | | 121 | 65 | 90 | | 122 | 96 | 91 | | 123 | 72 | 88 | | 124 | 85 | 99 | | 125 | 92 | 96 | | 126 | 82 | 99 | | 127 | 92 | 95 | | 128 | 61 | 93 | | 129 | 65 | 88 | | 130 | 50 | 95 | | 131 | 65 | 89 | | 132 | 70 | 95 | | 133 | 82 | 92 | | 134 | 60 | 88 | | 135 | 80 | 98 | | 136 | 78 | 96 | | 137 | 83 | 98 | | 138 | 69 | 89 | | 139 | 94 | 98 | | 140 | 100 | 92 | | 141 | 56 | 93 | | 142 | 65 | 99 | | 143 | 64 | 89 | | 144 | 80 | 99 | | 145 | 70 | 94 | | 146 | 54 | 90 | | 147 | 55 | 90 | | 148 | 55 | 92 | | 149 | 68 | 99 | | 150 | 66 | 90 | | 151 | 64 | 98 | | 152 | 56 | 89 | | 153 | 84 | 88 | | 154 | 80 | 92 | | 155 | 86 | 90 | | 156 | 83 | 98 | | 157 | 50 | 91 | | 158 | 100 | 90 | | 159 | 88 | 99 | | 160 | 62 | 99 | | 161 | 50 | 95 | | 162 | 59 | 91 | | 163 | 89 | 95 | | 164 | 91 | 97 | | 165 | 69 | 93 | | 166 | 61 | 89 | | 167 | 70 | 95 | | 168 | 89 | 92 | | 169 | 75 | 99 | | 170 | 98 | 95 | | 171 | 95 | 98 | | 172 | 83 | 99 | | 173 | 88 | 97 | | 174 | 90 | 99 | | 175 | 83 | 92 | | 176 | 60 | 93 | | 177 | 85 | 98 | | 178 | 56 | 93 | | 179 | 76 | 92 | | 180 | 50 | 98 | | 181 | 60 | 90 | | 182 | 100 | 89 | | 183 | 78 | 89 | | 184 | 64 | 99 | | 185 | 85 | 93 | | 186 | 87 | 92 | | 187 | 82 | 94 | | 188 | 57 | 91 | | 189 | 68 | 95 | | 190 | 75 | 94 | | 191 | 58 | 92 | | 192 | 77 | 91 | | 193 | 58 | 91 | | 194 | 66 | 92 | | 195 | 53 | 88 | | 196 | 92 | 91 | | 197 | 72 | 93 | | 198 | 95 | 89 | | 199 | 76 | 93 | | 200 | 75 | 91 | | 201 | 69 | 91 | | 202 | 58 | 95 | | 203 | 77 | 98 | | 204 | 100 | 99 | | 205 | 72 | 92 | | 206 | 60 | 92 | | 207 | 81 | 99 | | 208 | 75 | 91 | | 209 | 65 | 96 | | 210 | 68 | 95 | | 211 | 58 | 96 | | 212 | 95 | 90 | | 213 | 63 | 99 | | 214 | 65 | 96 | | 215 | 79 | 92 | | 216 | 56 | 90 | | 217 | 80 | 96 | | 218 | 60 | 97 | | 219 | 61 | 90 | | 220 | 61 | 91 | | 221 | 96 | 95 | | 222 | 91 | 98 | | 223 | 60 | 98 | | 224 | 94 | 99 | | 225 | 92 | 99 | | 226 | 88 | 90 | | 227 | 54 | 98 | | 228 | 69 | 95 | | 229 | 57 | 96 | | 230 | 76 | 89 | | 231 | 71 | 97 | | 232 | 98 | 96 | | 233 | 75 | 94 | | 234 | 77 | 91 | | 235 | 50 | 95 | | 236 | 63 | 98 | | 237 | 66 | 98 | | 238 | 58 | 91 | | 239 | 61 | 88 | | 240 | 57 | 96 | | | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

2. Brunswick has decided to build a new bowling ball manufacturing facility to support a newly found demand in South America. Facility planners are using data from manufacturing facilities in the United States to design the new South American facility. The controlling factor for the size of the new facility will be the size of the mold department, which manufactures the bowling ball cores. Use the provided data (data covers on year, equal to 240 working days) to determine the size of the bowling ball manufacturing mold department. Assume that a single shift is eight hours long, Brunswick utilizes two shifts, machine performance is 99%, the average machine is available for seven hours during each shift, the footprint of the machines are 100 square feet, and the average processing time per core is 20 minutes. 2. Brunswick has decided to build a new bowling ball manufacturing facility to support a newly found demand in South America. Facility planners are using data from manufacturing facilities in the United States to design the new South American facility. The controlling factor for the size of the new facility will be the size of the mold department, which manufactures the bowling ball cores. Use the provided data (data covers on year, equal to 240 working days) to determine the size of the bowling ball manufacturing mold department. Assume that a single shift is eight hours long, Brunswick utilizes two shifts, machine performance is 99%, the average machine is available for seven hours during each shift, the footprint of the machines are 100 square feet, and the average processing time per core is 20 minutes.

Brunswick utilizes 2 shifts = 16 hours

Available machine hours = 7 x 2 = 14 hours

Utilisation of mac hours = 99% = 13.86 hours

Foot print of the machines = 100 sq. ft

Avg. processing time per core = 20 minutes

Thus for one machine production = 13.86*60/20 = 41.58 units.

For 240days production per machine = 9979.20 units =9979 units.

Area occupied by the machine = 100 sq.ft

Hence hall should be built taking into account the area for the machine.

Suppose 89000 units are to be produced machine required =9

Area for machines = 9x100 =900 sq ft.

In addition, for labour files, and other things 1000 sqft is required

Hence 1900 sqft or more will be ideal if production is 89000 units per year

With 9 machines.

Homework Sourse

Homework Sourse