following MRP recor What will happen if the gross requiremen

Solution

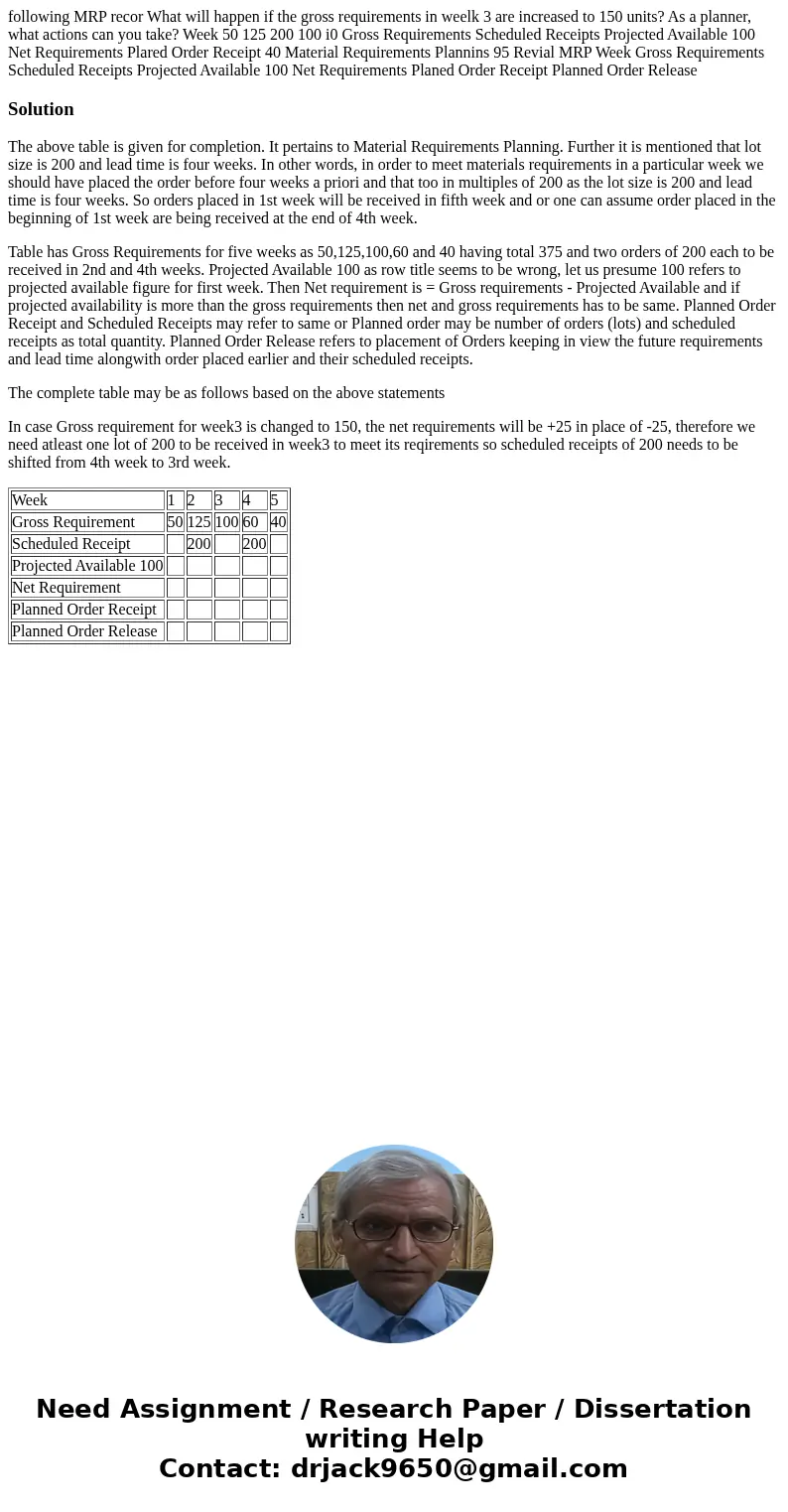

The above table is given for completion. It pertains to Material Requirements Planning. Further it is mentioned that lot size is 200 and lead time is four weeks. In other words, in order to meet materials requirements in a particular week we should have placed the order before four weeks a priori and that too in multiples of 200 as the lot size is 200 and lead time is four weeks. So orders placed in 1st week will be received in fifth week and or one can assume order placed in the beginning of 1st week are being received at the end of 4th week.

Table has Gross Requirements for five weeks as 50,125,100,60 and 40 having total 375 and two orders of 200 each to be received in 2nd and 4th weeks. Projected Available 100 as row title seems to be wrong, let us presume 100 refers to projected available figure for first week. Then Net requirement is = Gross requirements - Projected Available and if projected availability is more than the gross requirements then net and gross requirements has to be same. Planned Order Receipt and Scheduled Receipts may refer to same or Planned order may be number of orders (lots) and scheduled receipts as total quantity. Planned Order Release refers to placement of Orders keeping in view the future requirements and lead time alongwith order placed earlier and their scheduled receipts.

The complete table may be as follows based on the above statements

In case Gross requirement for week3 is changed to 150, the net requirements will be +25 in place of -25, therefore we need atleast one lot of 200 to be received in week3 to meet its reqirements so scheduled receipts of 200 needs to be shifted from 4th week to 3rd week.

| Week | 1 | 2 | 3 | 4 | 5 |

| Gross Requirement | 50 | 125 | 100 | 60 | 40 |

| Scheduled Receipt | 200 | 200 | |||

| Projected Available 100 | |||||

| Net Requirement | |||||

| Planned Order Receipt | |||||

| Planned Order Release |

Homework Sourse

Homework Sourse