Determine the required bolt preload tightening torque and th

Determine the required bolt preload, tightening torque, and the operating bolt stress for a joint with the following conditions: 10\" - 150lb weld neck flange. Flat-plate blind cover. 125 psi internal pressure. Soft cork-rubber gasket (3/16\").

Solution

Following assumptions are made in absence of sufficient data:

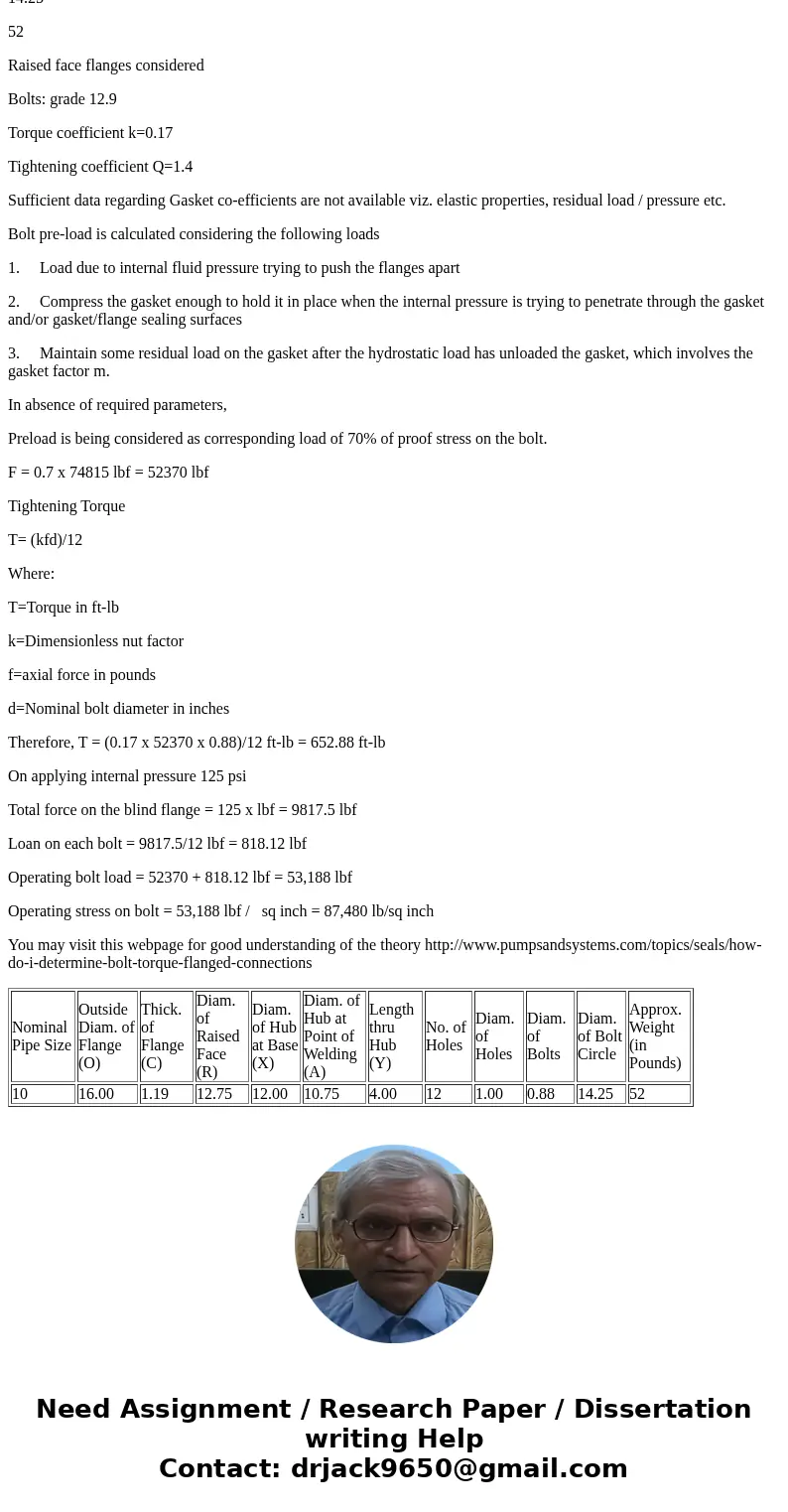

Flange as per ASME 16.5 150# (For dimensions please refer http://servicemetal.net/specSheets/150WeldNeck.pdf.pdf)

Nominal Pipe Size

Outside Diam. of Flange (O)

Thick. of Flange (C)

Diam. of Raised Face (R)

Diam. of Hub at Base (X)

Diam. of Hub at Point of Welding (A)

Length thru Hub (Y)

No. of Holes

Diam. of Holes

Diam. of Bolts

Diam. of Bolt Circle

Approx. Weight (in Pounds)

10

16.00

1.19

12.75

12.00

10.75

4.00

12

1.00

0.88

14.25

52

Raised face flanges considered

Bolts: grade 12.9

Torque coefficient k=0.17

Tightening coefficient Q=1.4

Sufficient data regarding Gasket co-efficients are not available viz. elastic properties, residual load / pressure etc.

Bolt pre-load is calculated considering the following loads

1. Load due to internal fluid pressure trying to push the flanges apart

2. Compress the gasket enough to hold it in place when the internal pressure is trying to penetrate through the gasket and/or gasket/flange sealing surfaces

3. Maintain some residual load on the gasket after the hydrostatic load has unloaded the gasket, which involves the gasket factor m.

In absence of required parameters,

Preload is being considered as corresponding load of 70% of proof stress on the bolt.

F = 0.7 x 74815 lbf = 52370 lbf

Tightening Torque

T= (kfd)/12

Where:

T=Torque in ft-lb

k=Dimensionless nut factor

f=axial force in pounds

d=Nominal bolt diameter in inches

Therefore, T = (0.17 x 52370 x 0.88)/12 ft-lb = 652.88 ft-lb

On applying internal pressure 125 psi

Total force on the blind flange = 125 x lbf = 9817.5 lbf

Loan on each bolt = 9817.5/12 lbf = 818.12 lbf

Operating bolt load = 52370 + 818.12 lbf = 53,188 lbf

Operating stress on bolt = 53,188 lbf / sq inch = 87,480 lb/sq inch

You may visit this webpage for good understanding of the theory http://www.pumpsandsystems.com/topics/seals/how-do-i-determine-bolt-torque-flanged-connections

| Nominal Pipe Size | Outside Diam. of Flange (O) | Thick. of Flange (C) | Diam. of Raised Face (R) | Diam. of Hub at Base (X) | Diam. of Hub at Point of Welding (A) | Length thru Hub (Y) | No. of Holes | Diam. of Holes | Diam. of Bolts | Diam. of Bolt Circle | Approx. Weight (in Pounds) |

| 10 | 16.00 | 1.19 | 12.75 | 12.00 | 10.75 | 4.00 | 12 | 1.00 | 0.88 | 14.25 | 52 |

Homework Sourse

Homework Sourse