Manufacturing Processes Production Semester 1 2016 Xs compa

Manufacturing Processes & Production

Semester 1, 2016

X’s company, the world’s largest manufacturer, seeks to extend business in New Zealand. To develop manufacturing plants, the X’s company called on manufacturing experts to deliver a complete report to advise the company for their keys products as followings

Group 6: Refrigerator

Each product contains different parts and each part is made from various materials and processes. The material and manufacturing processes are chosen based on the design intent. As six groups have been engaged in this project, for each group member, you are responsible to undertake one of the following topics and produce a report types to collect all necessary key information. Each member will select at least two components of the product and choose the most suitable process for manufacturing.

Section 1: Manufacturing Production: Provide several keys factors and methods needed for manufacturing production controls.

Quality control in manufacturing

Inventory control in manufacturing

Facility layout

Logistics and transportation

Section 2: Manufacturing Process: for the each chosen part, list all the design intent and discuss how to select the material used and manufacturing process used to make parts. Also, provide a summary of each chosen process as below

Casting

Forming

Extrusion and Drawing

Powder-Metal

Plastic Forming and shaping

Rapid Prototyping

Machining

Abrasive machining and finishing

Welding

Surface treatment, coatings

Section 3: Computer-Integrated Manufacturing: Provide details how computer systems and communication networks affect product development and manufacturing selection, the topics are:

Cellular Manufacturing

Flexible Manufacturing

Holonic Manufacturing

Just-in-time Production

Lean Manufacturing

Communications Network in Manufacturing

Artificial Intelligence

Economic Consideration

Solution

Solution :

Section 1 :

Quality control :-

Quality control, or QC for short, is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as \"A part of quality management focused on fulfilling quality requirements\".

This approach places an emphasis on three aspects:

Controls include product inspection, where every product is examined visually, and often using a stereo microscope for fine detail before the product is sold into the external market. Inspectors will be provided with lists and descriptions of unacceptable product defects such ascracks or surface blemishes for example.

The quality of the outputs is at risk if any of these three aspects is deficient in any way.

Quality control emphasizes testing of products to uncover defects and reporting to management who make the decision to allow or deny product release, whereas quality assurance attempts to improve and stabilize production (and associated processes) to avoid, or at least minimize, issues which led to the defect(s) in the first place. For contract work, particularly work awarded by government agencies, quality control issues are among the top reasons for not renewing a contract.

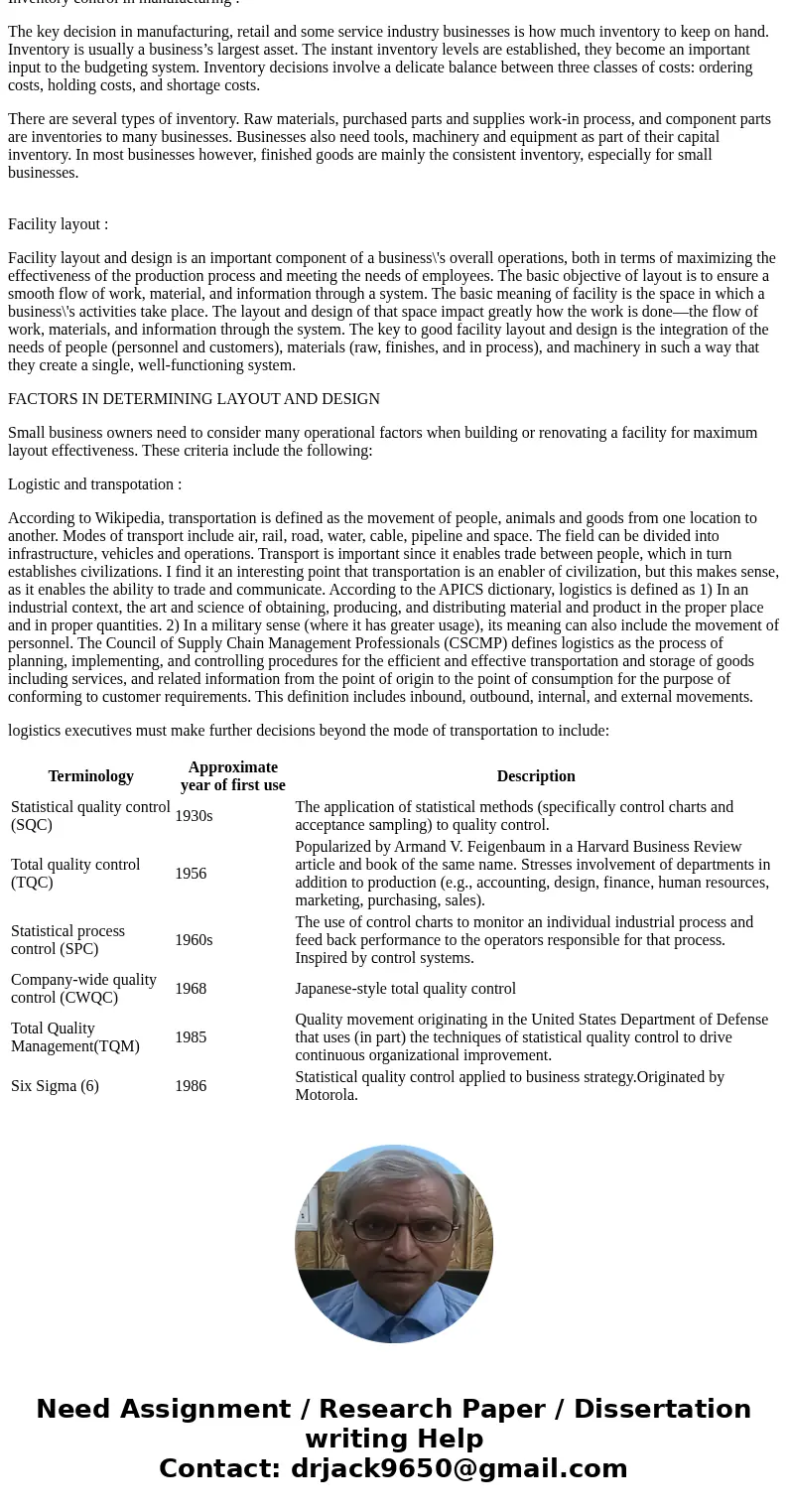

There is a tendency for individual consultants and organizations to name their own unique approaches to quality control—a few of these have ended up in widespread use:

Inventory control in manufacturing :

The key decision in manufacturing, retail and some service industry businesses is how much inventory to keep on hand. Inventory is usually a business’s largest asset. The instant inventory levels are established, they become an important input to the budgeting system. Inventory decisions involve a delicate balance between three classes of costs: ordering costs, holding costs, and shortage costs.

There are several types of inventory. Raw materials, purchased parts and supplies work-in process, and component parts are inventories to many businesses. Businesses also need tools, machinery and equipment as part of their capital inventory. In most businesses however, finished goods are mainly the consistent inventory, especially for small businesses.

Facility layout :

Facility layout and design is an important component of a business\'s overall operations, both in terms of maximizing the effectiveness of the production process and meeting the needs of employees. The basic objective of layout is to ensure a smooth flow of work, material, and information through a system. The basic meaning of facility is the space in which a business\'s activities take place. The layout and design of that space impact greatly how the work is done—the flow of work, materials, and information through the system. The key to good facility layout and design is the integration of the needs of people (personnel and customers), materials (raw, finishes, and in process), and machinery in such a way that they create a single, well-functioning system.

FACTORS IN DETERMINING LAYOUT AND DESIGN

Small business owners need to consider many operational factors when building or renovating a facility for maximum layout effectiveness. These criteria include the following:

Logistic and transpotation :

According to Wikipedia, transportation is defined as the movement of people, animals and goods from one location to another. Modes of transport include air, rail, road, water, cable, pipeline and space. The field can be divided into infrastructure, vehicles and operations. Transport is important since it enables trade between people, which in turn establishes civilizations. I find it an interesting point that transportation is an enabler of civilization, but this makes sense, as it enables the ability to trade and communicate. According to the APICS dictionary, logistics is defined as 1) In an industrial context, the art and science of obtaining, producing, and distributing material and product in the proper place and in proper quantities. 2) In a military sense (where it has greater usage), its meaning can also include the movement of personnel. The Council of Supply Chain Management Professionals (CSCMP) defines logistics as the process of planning, implementing, and controlling procedures for the efficient and effective transportation and storage of goods including services, and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements. This definition includes inbound, outbound, internal, and external movements.

logistics executives must make further decisions beyond the mode of transportation to include:

| Terminology | Approximate year of first use | Description |

|---|---|---|

| Statistical quality control (SQC) | 1930s | The application of statistical methods (specifically control charts and acceptance sampling) to quality control. |

| Total quality control (TQC) | 1956 | Popularized by Armand V. Feigenbaum in a Harvard Business Review article and book of the same name. Stresses involvement of departments in addition to production (e.g., accounting, design, finance, human resources, marketing, purchasing, sales). |

| Statistical process control (SPC) | 1960s | The use of control charts to monitor an individual industrial process and feed back performance to the operators responsible for that process. Inspired by control systems. |

| Company-wide quality control (CWQC) | 1968 | Japanese-style total quality control |

| Total Quality Management(TQM) | 1985 | Quality movement originating in the United States Department of Defense that uses (in part) the techniques of statistical quality control to drive continuous organizational improvement. |

| Six Sigma (6) | 1986 | Statistical quality control applied to business strategy.Originated by Motorola. |

Homework Sourse

Homework Sourse