You are a systems engineer assigned to a project that is dev

You are a systems engineer assigned to a project that is developing a valve control architecture for a water treatment plant. Your group will integrate a software module into a feedback software program that provides a rate per minute of treated (clean) water coming from the last filtration step. Use this picture as a guide in Systems Engineering, such as Preliminary System Design, Detailed Design, System Test, Evaluation and Validation, System Analysis and Design Evaluation, Optimization,and any internet source to complete this assignment. Use can use any of these above to analyze this system.

Solution

Automation of water treatment plants improves operation efficiency and effluent quality. Supervisory Control And Data Acquisition (SCADA) is an automated system consisting of both software and hardware, that source and control data from a remote site. It is an affordable tool, which can be customised to place control and information technology within the reach of smaller public and private facilities.

The operators of Oahu, a wastewater treatment plant in Hawaii, remotely monitor and control 65 wastewater-pumping stations and 12 wastewater treatment facilities spread over 600 square miles. Functions being performed in this SCADA system include lead-lag pump control. The automation process used consists of PC-based Human Machine Interface (HMI)/SCADA system. This software technology implementation consists of three key steps:

In this article we discuss the software architecture used in automation of water treatment plants.

Software architecture

The software architecture of SCADA system software refers to the internal design of the system. The utilisation of equipment-based architecture controls labour costs related to the software system development, startup and maintenance. A user of equipment-based software connects equipments to develop applications. An alternate equipment can operate a run/standby pump system by configuring the equipment by naming parameters such as number of pumps in the system and run time for each pump.

Based on the water level in water tower, valves or pumps are automatically operated using an equipment -based on/off process controller. A Proportional-Integral-Derivative (PID) algorithm provides loop-controlled operation of variable-speed chemical feed pumps. It uses an input value and a set point value to automatically maintain process within set limits. Multiple objects are interconnected to build up more complex applications.

Ethernet is a Local Area Network (LAN) protocol that uses a bus or star topology and supports data transfer rates. Ethernet collects information and connects different hardware and software sections, and can be used for treatment applications in water and wastewater plant. Ethernet-based hardware is being used extensively since it is comparatively simple to integrate software, which uses Transfer Control Protocol/Internet Protocol (TCP/IP)-based network. Ethernet shares technology to reduce integration problems and ensures that the software and hardware work well together.

Software packages, which are now available, connect through Ethernet and permit many servers and clients to connect across a network. For developing distributed applications, multiple-server and multiple-client ability are useful. HMI/SCADA software can leverage the Internet for water or wastewater treatment plants. This Internet technology can be used as a reporting and troubleshooting tool in the treatment plants.

Users can log in from any part of the world and observe the reservoir level and the flow rate of pumps. If Water District Two purchases water from Water District One, information regarding the water availability can be known. They can even operate and open valves, through the Internet, to get enough water into its system.

Equipment like pumps and valves can be linked to SCADA software to detect and rectify any problems. A maintenance operator can use a laptop, connected to the central station, to operate and test pumps and valves. HMI/SCADA software in automation of treatment plants has increased customer service and efficiency of the process.

33. DETAILS OF DESIGN AND CONSTRUCTION

33.1 Minimum Size

No public gravity sewer conveying raw wastewater shall be less than 8 inches (200 mm) in diameter.

33.2 Depth

In general, sewers should be sufficiently deep to receive wastewater from basements and to prevent freezing. Insulation shall be provided for sewers that cannot be placed at a depth sufficient to prevent freezing.

33.3 Buoyancy

Buoyancy of sewers shall be considered and flotation of the pipe shall be prevented with appropriate construction where high groundwater conditions are anticipated.

33.4 Slope

33.41 Recommended Minimum Slopes

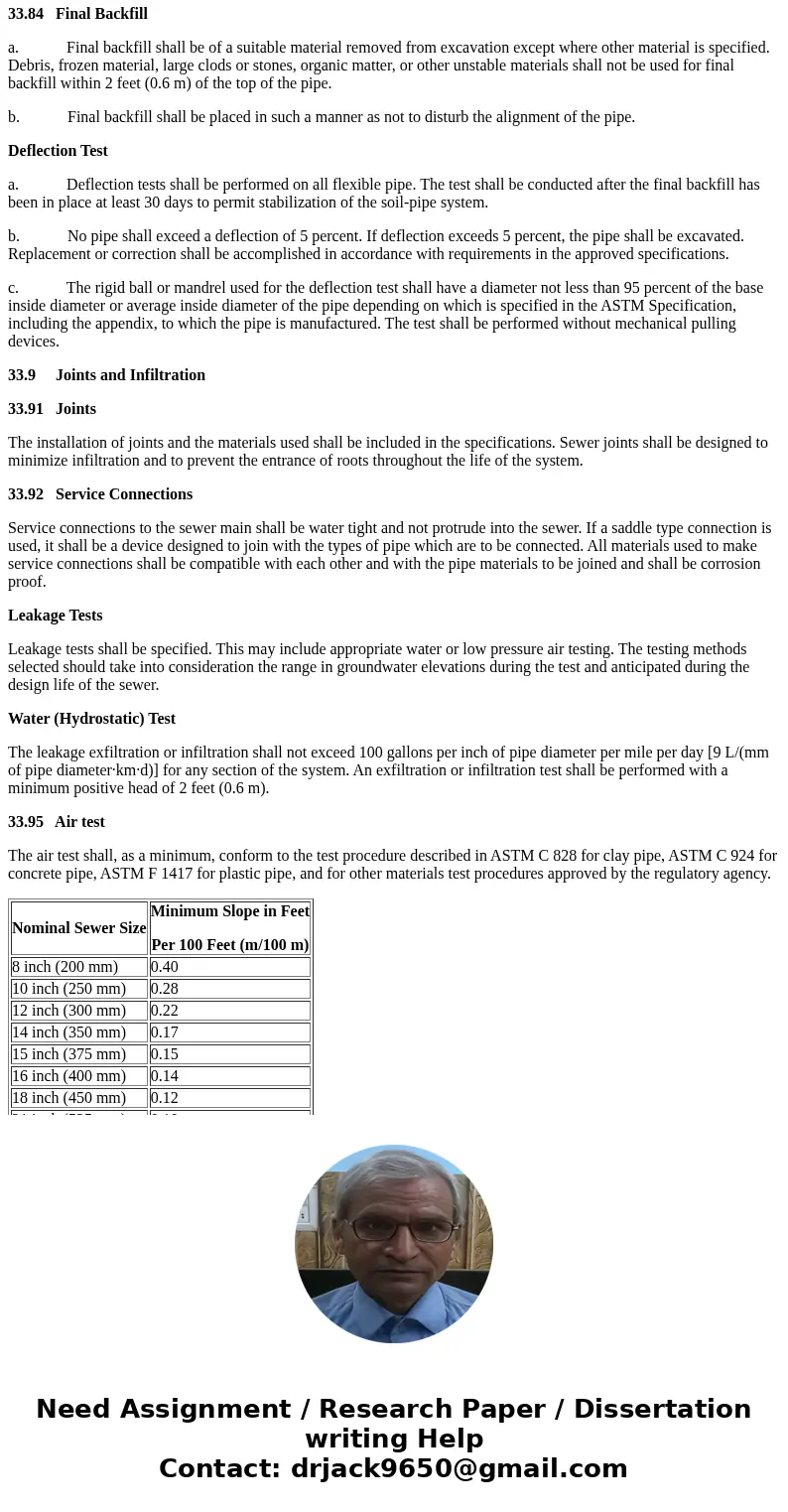

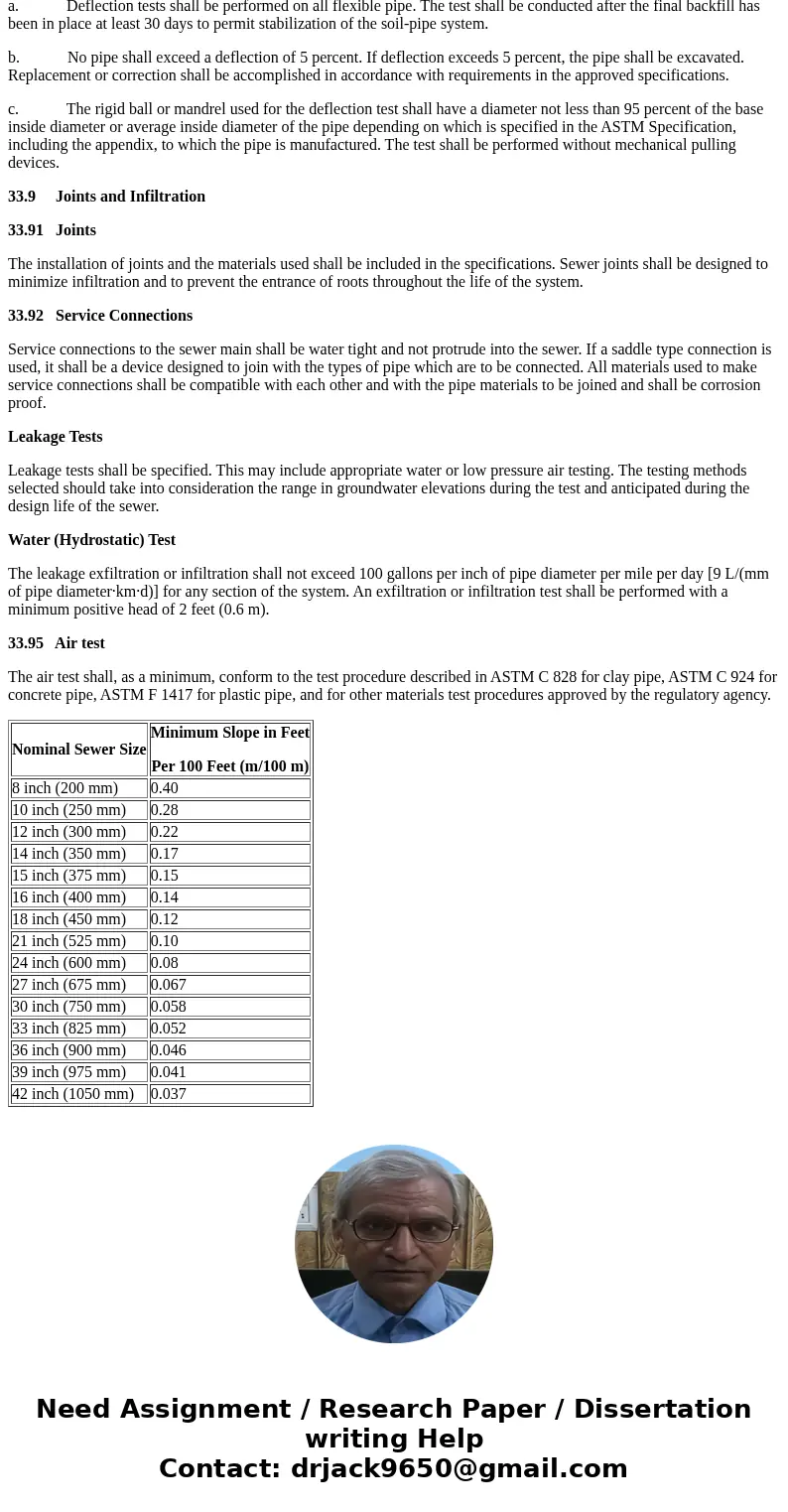

All sewers shall be designed and constructed to give mean velocities, when flowing full, of not less than 2.0 feet per second (0.6 m/s), based on Manning\'s formula using an \"n\" value of 0.013. The following are the recommended minimum slopes which should be provided for sewers 42 inches (1050 mm) or less; however, slopes greater than these may be desirable for construction, to control sewer gases or to maintain self-cleansing velocities at all rates of flow within the design limits.

Nominal Sewer Size

Minimum Slope in Feet

Per 100 Feet (m/100 m)

8 inch (200 mm)

0.40

10 inch (250 mm)

0.28

12 inch (300 mm)

0.22

14 inch (350 mm)

0.17

15 inch (375 mm)

0.15

16 inch (400 mm)

0.14

18 inch (450 mm)

0.12

21 inch (525 mm)

0.10

24 inch (600 mm)

0.08

27 inch (675 mm)

0.067

30 inch (750 mm)

0.058

33 inch (825 mm)

0.052

36 inch (900 mm)

0.046

39 inch (975 mm)

0.041

42 inch (1050 mm)

0.037

Sewers 48 inches (1200 mm) or larger should be designed and constructed to give mean velocities, when flowing full, of not less than 3.0 feet per second (0.9 m/s), based on Manning’s formula using an “n” value of 0.013.

33.42 Minimum Flow Depths

Slopes which are slightly less than the recommended minimum slopes may be permitted. Such decreased slopes may be considered where the depth of flow will be 0.3 of the diameter or greater for design average flow. The operating authority of the sewer system will give written assurance to the appropriate reviewing authority that any additional sewer maintenance required by reduced slopes will be provided.

33.43 Minimize Solids Deposition

The pipe diameter and slope shall be selected to obtain the greatest practical velocities to minimize settling problems. Oversize sewers will not be approved to justify using flatter slopes. If the proposed slope is less than the minimum slope of the smallest pipe which can accommodate the design peak hourly flow, the actual depths and velocities at minimum, average, and design maximum day and peak hourly flow for each design section of the sewer shall be calculated by the design engineer and be included with the plans.

Slope Between Manholes

Sewers shall be laid with uniform slope between manholes.

33.45 High Velocity Protection

Where velocities greater than 15 feet per second (4.6 m/s) are attained, special provision shall be made to protect against displacement by erosion and impact.

33.46 Steep Slope Protection

Sewers on 20 percent slopes or greater shall be anchored securely with concrete, or equal, anchors spaced as follows:

a. Not over 36 feet (11 m) center to center on grades 20 percent and up to 35 percent;

b. Not over 24 feet (7.3 m) center to center on grades 35 percent and up to 50 percent; and

c. Not over 16 feet (4.9 m) center to center on grades 50 percent and over.

Alignment

In general, sewers 24 inches (600 mm) or less shall be laid with straight alignment between manholes. Straight alignment shall be checked by either using a laser beam or lamping.

Curvilinear alignment of sewers larger than 24 inches (600 mm) may be considered on a case by case basis provided compression joints are specified and ASTM or specific pipe manufacturers\' maximum allowable pipe joint deflection limits are not exceeded. Curvilinear sewers shall be limited to simple curves which start and end at manholes. When curvilinear sewers are proposed, the recommended minimum slopes indicated in Paragraph 33.41 must be increased accordingly to provide a minimum velocity of 2.0 feet per second (0.6 m/s) when flowing full.

33.6 Changes in Pipe Size

When a smaller sewer joins a large one, the invert of the larger sewer should be lowered sufficiently to maintain the same energy gradient. An approximate method for securing these results is to place the 0.8 depth point of both sewers at the same elevation.

Sewer extensions should be designed for projected flows even when the diameter of the receiving sewer is less than the diameter of the proposed extension at a manhole constructed in accordance with Section 34 with special consideration of an appropriate flow channel to minimize turbulence when there is a change in sewer size. The appropriate reviewing authority may require a schedule for construction of future downstream sewer relief.

33.7 Materials

Any generally accepted material for sewers will be given consideration, but the material selected should be adapted to local conditions, such as: character of industrial wastes, possibility of septicity, soil characteristics, exceptionally heavy external loadings, abrasion, corrosion, and similar problems.

Suitable couplings complying with ASTM specifications shall be used for joining dissimilar materials. The leakage limitations on these joints shall

All sewers shall be designed to prevent damage from superimposed live, dead, and frost induced loads. Proper allowance for loads on the sewer shall be made because of soil and potential groundwater conditions, as well as the width and depth of trench. Where necessary, special bedding, haunching and initial backfill, concrete cradle, or other special construction shall be used to withstand anticipated potential superimposed loading or loss of trench wall stability. See ASTM D 2321 or ASTM C 12 when appropriate.

For new pipe materials for which ASTM standards have not been established, the design engineer shall provide complete pipe specifications and installation specifications developed on the basis of criteria adequately documented and certified in writing by the pipe manufacturer to be satisfactory for the specific detailed plans.

33.8 Installation

33.81 Standards

Installation specifications shall contain appropriate requirements based on the criteria, standards, and requirements established by industry in its technical publications. Requirements shall be set forth in the specifications for the pipe and methods of bedding and backfilling thereof so as not to damage the pipe or its joints, impede cleaning operations and future tapping, nor create excessive side fill pressures and ovalation of the pipe, nor seriously impair flow capacity.

Trenching

a. The width of the trench shall be ample to allow the pipe to be laid and jointed properly and to allow the bedding and haunching to be placed and compacted to adequately support the pipe. The trench sides shall be kept as nearly vertical as possible. When wider trenches are specified, appropriate bedding class and pipe strength shall be used.

In unsupported, unstable soil the size and stiffness of the pipe, stiffness of the embedment and insitu soil and depth of cover shall be considered in determining the minimum trench width necessary to adequately support the pipe.

b. Ledge rock, boulders, and large stones shall be removed to provide a minimum clearance of 4 inches (100 mm) below and on each side of all pipe(s).

33.83 Bedding, Haunching, and Initial Backfill

a. Bedding Classes A, B, C, or crushed stone as described in ASTM C 12 shall be used and carefully compacted for all rigid pipe provided the proper strength pipe is used with the specified bedding to support the anticipated load, based on the type soil encountered and potential ground water conditions.

b. Embedment materials for bedding, haunching and initial backfill, Classes I, II, or III, as described in ASTM D 2321, shall be used and carefully compacted for all flexible pipe provided the proper strength pipe is used with the specified bedding to support the anticipated load, based on the type soil encountered and potential groundwater conditions.

c. All water entering the excavations or other parts of the work shall be removed until all the work has been completed. No sanitary sewer shall be used for the disposal of trench water, unless specifically approved by the engineer, and then only if the trench water does not ultimately arrive at existing pumping or wastewater treatment facilities.

33.84 Final Backfill

a. Final backfill shall be of a suitable material removed from excavation except where other material is specified. Debris, frozen material, large clods or stones, organic matter, or other unstable materials shall not be used for final backfill within 2 feet (0.6 m) of the top of the pipe.

b. Final backfill shall be placed in such a manner as not to disturb the alignment of the pipe.

Deflection Test

a. Deflection tests shall be performed on all flexible pipe. The test shall be conducted after the final backfill has been in place at least 30 days to permit stabilization of the soil-pipe system.

b. No pipe shall exceed a deflection of 5 percent. If deflection exceeds 5 percent, the pipe shall be excavated. Replacement or correction shall be accomplished in accordance with requirements in the approved specifications.

c. The rigid ball or mandrel used for the deflection test shall have a diameter not less than 95 percent of the base inside diameter or average inside diameter of the pipe depending on which is specified in the ASTM Specification, including the appendix, to which the pipe is manufactured. The test shall be performed without mechanical pulling devices.

33.9 Joints and Infiltration

33.91 Joints

The installation of joints and the materials used shall be included in the specifications. Sewer joints shall be designed to minimize infiltration and to prevent the entrance of roots throughout the life of the system.

33.92 Service Connections

Service connections to the sewer main shall be water tight and not protrude into the sewer. If a saddle type connection is used, it shall be a device designed to join with the types of pipe which are to be connected. All materials used to make service connections shall be compatible with each other and with the pipe materials to be joined and shall be corrosion proof.

Leakage Tests

Leakage tests shall be specified. This may include appropriate water or low pressure air testing. The testing methods selected should take into consideration the range in groundwater elevations during the test and anticipated during the design life of the sewer.

Water (Hydrostatic) Test

The leakage exfiltration or infiltration shall not exceed 100 gallons per inch of pipe diameter per mile per day [9 L/(mm of pipe diameter·km·d)] for any section of the system. An exfiltration or infiltration test shall be performed with a minimum positive head of 2 feet (0.6 m).

33.95 Air test

The air test shall, as a minimum, conform to the test procedure described in ASTM C 828 for clay pipe, ASTM C 924 for concrete pipe, ASTM F 1417 for plastic pipe, and for other materials test procedures approved by the regulatory agency.

| Nominal Sewer Size | Minimum Slope in Feet Per 100 Feet (m/100 m) |

|---|---|

| 8 inch (200 mm) | 0.40 |

| 10 inch (250 mm) | 0.28 |

| 12 inch (300 mm) | 0.22 |

| 14 inch (350 mm) | 0.17 |

| 15 inch (375 mm) | 0.15 |

| 16 inch (400 mm) | 0.14 |

| 18 inch (450 mm) | 0.12 |

| 21 inch (525 mm) | 0.10 |

| 24 inch (600 mm) | 0.08 |

| 27 inch (675 mm) | 0.067 |

| 30 inch (750 mm) | 0.058 |

| 33 inch (825 mm) | 0.052 |

| 36 inch (900 mm) | 0.046 |

| 39 inch (975 mm) | 0.041 |

| 42 inch (1050 mm) | 0.037 |

Homework Sourse

Homework Sourse