A Company that makes shopping carts for supermarkets and oth

A Company that makes shopping carts for supermarkets and other stores recently purchased some new equipment that reduces the labor content of the jobs needed to produce the shopping carts. Prior to buying the new equipment, the company used 6 workers, who produced an average of 78 carts per hour. Workers receive $10 per hour, and machine coast was $36 per hour. With the new equipment, it was possible to transfer one of the workers to another department, and equipment cost increased by $13 per hour while output increased by four carts per hour.

a) Compute the multifactor productivity (MFP) (labor plus equipment) under the Prior to buying the new equipment. The MFP (carts/$) = Blank 1 (round to 4 decimal places).

b) Compute the % growth in productivity between the Prior to and after buying the new equipment. The growth in productivity = Blank 2 % (round to 2 decimal places)

12 points

Question 2

Given is a historical time series for job services demand in the prior 6 months.

Month

Demand

1

799

2

816

3

789

4

814

5

815

6

805

The Period 6 forecast by using weighted moving average with weights of 0.05, 0.25, 0.40, and 0.30 = Blank 1 (in 2 decimal places)

| Month | Demand |

| 1 | 799 |

| 2 | 816 |

| 3 | 789 |

| 4 | 814 |

| 5 | 815 |

| 6 | 805 |

Solution

Multifactor productivity refers to rate of output based on various inputs like labour, capital, technology whereas single factor productivity is based on only one factor like labour productivity, manchine, capital productivity etc.

It is given that prior to new machine 6 workers produced 78 units per hour. In terms of cost of inputs, it includes machine cost of $36 per hour whereas worker gets $10 per hour. Therefore the total cost of inputs (labour + machine) works out as $96 per hour for output of 78 units, therefore prior MFP is 78/96 % .

Number of carts per $ = 78/96 = .8125

With the new machine the output is increased by 4 units which means 82 units per hour whereas number of workers are decreased by one that means, labour input cost is $50 per hour but machine cost is increased by $13 per hour. Therefore with new machine the output is 82 units and total cost of inputs (labour + machine) is $102 per hour, hence new MFP is 82/102 %

Prior MFP = 78/96 % = 81.25 whereas with new machine MFP = 82/102 % = 80.39

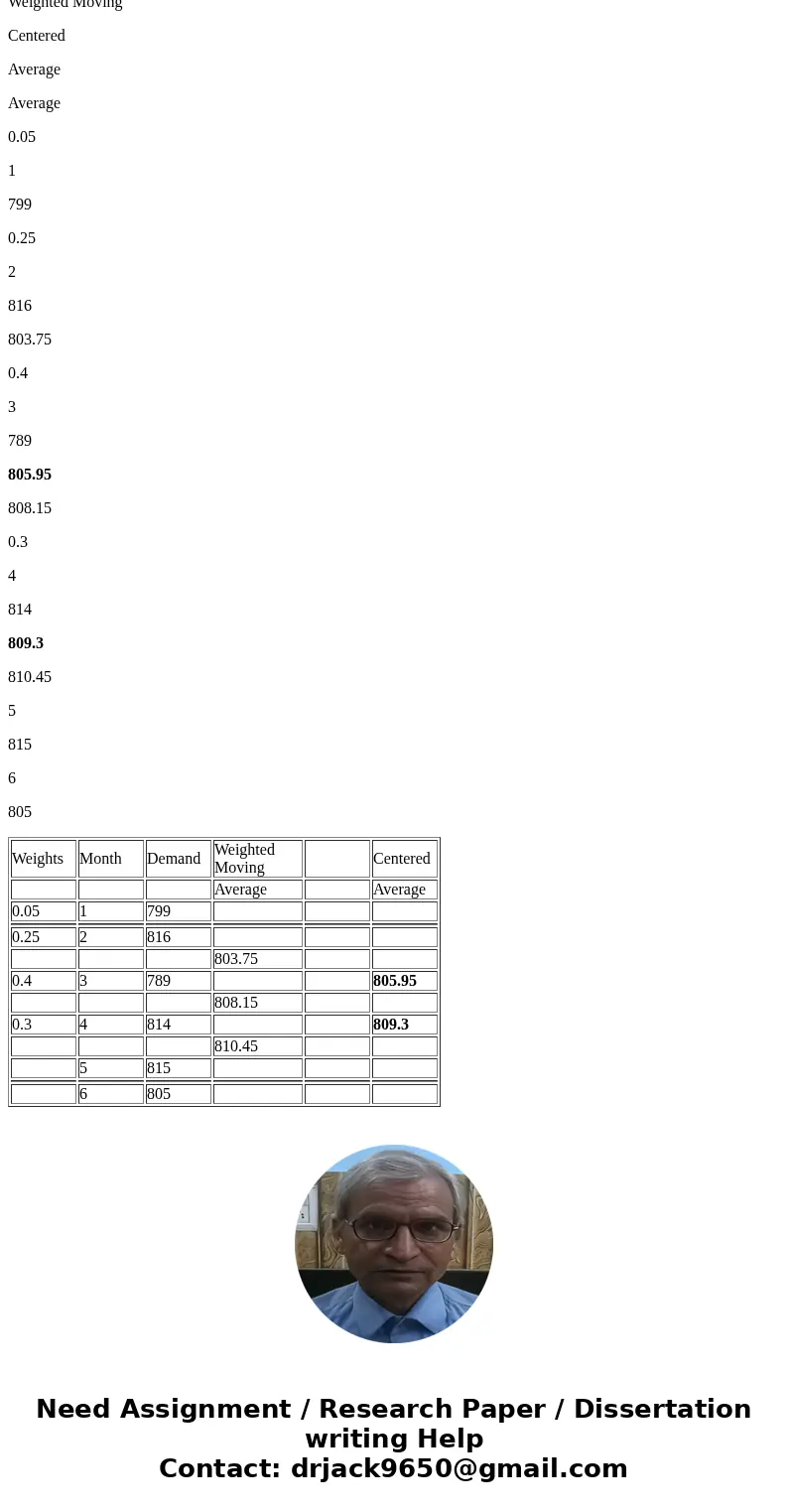

Question 2 is regarding finding weighted moving average with weights .05, .25, .40, .30 which means we are required to have centered 4 period weighted moving average method.

To begin with weights are multiplied with the figures of first four months in the given order and their sum is written in the middle of four months that is middle of 2nd and third month. Again weights are muliplied with the four months data but starting with 2nd month and their sum is placed between 3rd and 4th months. Again the exercise is repeated starting with 3rd month and the sum is written between 4th and 5th months.

Now the above mentioned averages in between the months are averaged so as to get the figures fgor 3rd and 4th month as shown inthe table below:

Weights

Month

Demand

Weighted Moving

Centered

Average

Average

0.05

1

799

0.25

2

816

803.75

0.4

3

789

805.95

808.15

0.3

4

814

809.3

810.45

5

815

6

805

| Weights | Month | Demand | Weighted Moving | Centered | |

| Average | Average | ||||

| 0.05 | 1 | 799 | |||

| 0.25 | 2 | 816 | |||

| 803.75 | |||||

| 0.4 | 3 | 789 | 805.95 | ||

| 808.15 | |||||

| 0.3 | 4 | 814 | 809.3 | ||

| 810.45 | |||||

| 5 | 815 | ||||

| 6 | 805 |

Homework Sourse

Homework Sourse