An inspector is inspecting the surface finish of a plastic i

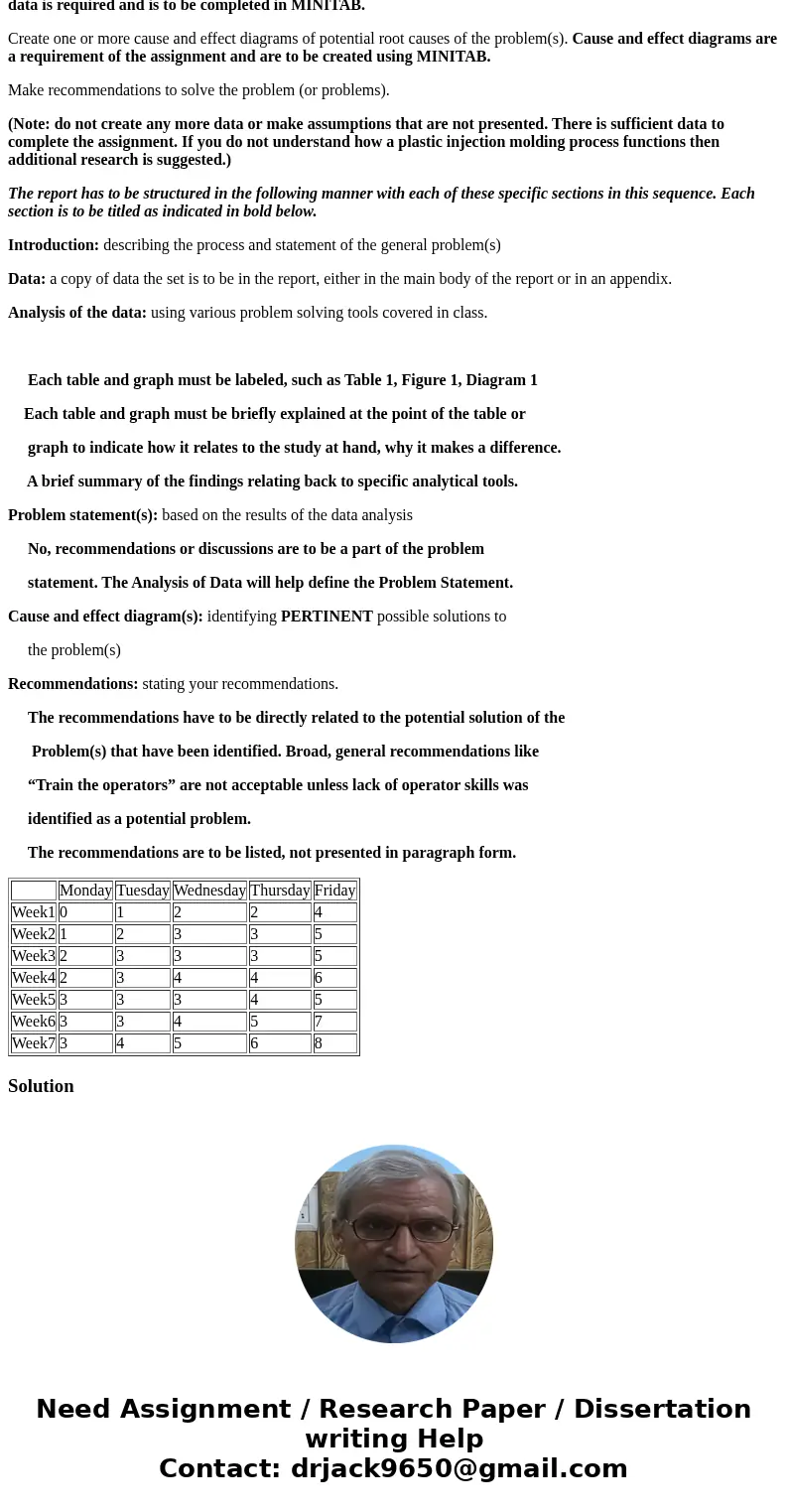

An inspector is inspecting the surface finish of a plastic injection molded product. Each day 1000 products are produced and 100 are inspected. The inspector makes an accept/reject decision based on a visual examination comparing the product’s surface finish against an acceptable sample. The surface finish is a cosmetic, decorative quality characteristic of the product, that if blemished affects the product’s marketability. At the end of each day the inspector counts the number of defective products. The following are the results of 35 days of inspection.

Monday

Tuesday

Wednesday

Thursday

Friday

Week1

0

1

2

2

4

Week2

1

2

3

3

5

Week3

2

3

3

3

5

Week4

2

3

4

4

6

Week5

3

3

3

4

5

Week6

3

3

4

5

7

Week7

3

4

5

6

8

Your manager states there are too many defective products being produced. He has assigned you the task of determining if a problem(s) exist and suggest potential solutions.

Analyze the data using the appropriate descriptive, presentational, analytical and problem solving tools such as descriptive statistics, frequency distributions, Histograms, Pareto diagrams, run charts, etc. Graphical analysis of the data is required and is to be completed in MINITAB.

Create one or more cause and effect diagrams of potential root causes of the problem(s). Cause and effect diagrams are a requirement of the assignment and are to be created using MINITAB.

Make recommendations to solve the problem (or problems).

(Note: do not create any more data or make assumptions that are not presented. There is sufficient data to complete the assignment. If you do not understand how a plastic injection molding process functions then additional research is suggested.)

The report has to be structured in the following manner with each of these specific sections in this sequence. Each section is to be titled as indicated in bold below.

Introduction: describing the process and statement of the general problem(s)

Data: a copy of data the set is to be in the report, either in the main body of the report or in an appendix.

Analysis of the data: using various problem solving tools covered in class.

Each table and graph must be labeled, such as Table 1, Figure 1, Diagram 1

Each table and graph must be briefly explained at the point of the table or

graph to indicate how it relates to the study at hand, why it makes a difference.

A brief summary of the findings relating back to specific analytical tools.

Problem statement(s): based on the results of the data analysis

No, recommendations or discussions are to be a part of the problem

statement. The Analysis of Data will help define the Problem Statement.

Cause and effect diagram(s): identifying PERTINENT possible solutions to

the problem(s)

Recommendations: stating your recommendations.

The recommendations have to be directly related to the potential solution of the

Problem(s) that have been identified. Broad, general recommendations like

“Train the operators” are not acceptable unless lack of operator skills was

identified as a potential problem.

The recommendations are to be listed, not presented in paragraph form.

| Monday | Tuesday | Wednesday | Thursday | Friday | |

| Week1 | 0 | 1 | 2 | 2 | 4 |

| Week2 | 1 | 2 | 3 | 3 | 5 |

| Week3 | 2 | 3 | 3 | 3 | 5 |

| Week4 | 2 | 3 | 4 | 4 | 6 |

| Week5 | 3 | 3 | 3 | 4 | 5 |

| Week6 | 3 | 3 | 4 | 5 | 7 |

| Week7 | 3 | 4 | 5 | 6 | 8 |

Solution

Homework Sourse

Homework Sourse