Scribners Corporation produces fine papers in three producti

Scribners Corporation produces fine papers in three production departments-Pulping Drying, and Finishing. In the Pulping Department, raw materials such as wood fiber and rag cotton are mechanically and chemically treated to separate their fibers. The result is a thick slurry of fibers. In the Drying Department, the wet fibers transferred from the Pulping Department are laid down on porous webs, pressed to remove excess liquid, and dried in ovens. In the Finishing Department, the dried paper is coated, cut, and spooled onto reels. The company uses the weighted-average method in its process costing system. Data for March for the Drying Department follow Percent Com Work in process inventory, March 1 Work in process inventory, March 31 Units Pu 3,700 100% 8,500 100% version 80% 80% Pulping cost in work in process inventory, March 1 Conversion cost in work in process inventory, March 1 Units transferred to the next production department Pulping cost added during March Conversion cost added during March S 2,516 S 1,517 162,500 $ 118,894 74,668 No materials are added in the Drying Department. Pulping cost represents the costs of the wet fibers transfemed in from the Pulping Department. Wet fiber is processed in the Drying Department in batches; each unit in the above table is a batch and one batch of wet fibers produces a set amount of dried paper hat is passed on to the Finishing Department. Required: 1. Determine the equivalent units for March for pulping and conversion. Pulping Equivalent units of production 2. Compute the costs per equivalent unit for March for pulping and conversion. (Round your answers to 2 Cost per equivalent unit the total cost of ending work in process inventory and the total cost of units transferred to the Finishing Department in March. (Round your intermediate calculations to 2 decimal places and your final answers to the nearest whole dollar.)

Solution

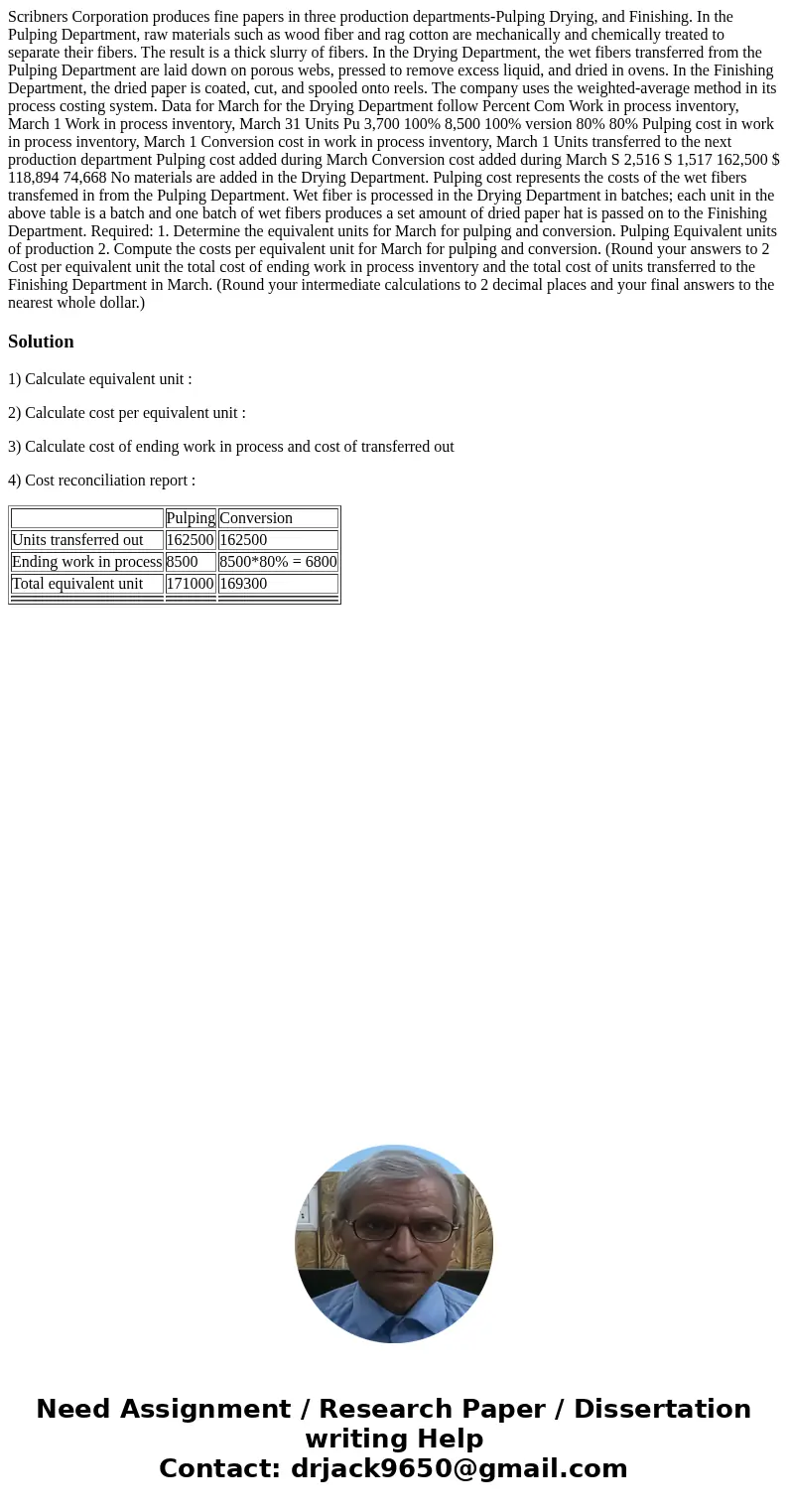

1) Calculate equivalent unit :

2) Calculate cost per equivalent unit :

3) Calculate cost of ending work in process and cost of transferred out

4) Cost reconciliation report :

| Pulping | Conversion | |

| Units transferred out | 162500 | 162500 |

| Ending work in process | 8500 | 8500*80% = 6800 |

| Total equivalent unit | 171000 | 169300 |

Homework Sourse

Homework Sourse