6 Management Sustainability and Supply Chain Man not purcnas

Solution

1.15

Production in December = 6,600 vans

Labor productivity = 0.1 vans per labor-hours

So, labor-hours employed = Production / labor productivity = 6,600 / 0.10 = 66,000 lavor-hours

(a)

No. of workers = 300

So, average hours worked per month = 66000 / 300 = 220 hours

(b)

SImilarly, for the labor productivity being 0.11 vans per labor-hours,

Average hours worked per month = 6,600 / (300 x 0.11) = 200 hours

1.16

Output = 52 x $90 + 80 x $198 = $20,520

Input = 45 x 8 labor-hours = 360 labor-hours

Labor productivity = Otput / Input = 20,520 / 360 dollar per labor-hours = 57 dollars per labor hour

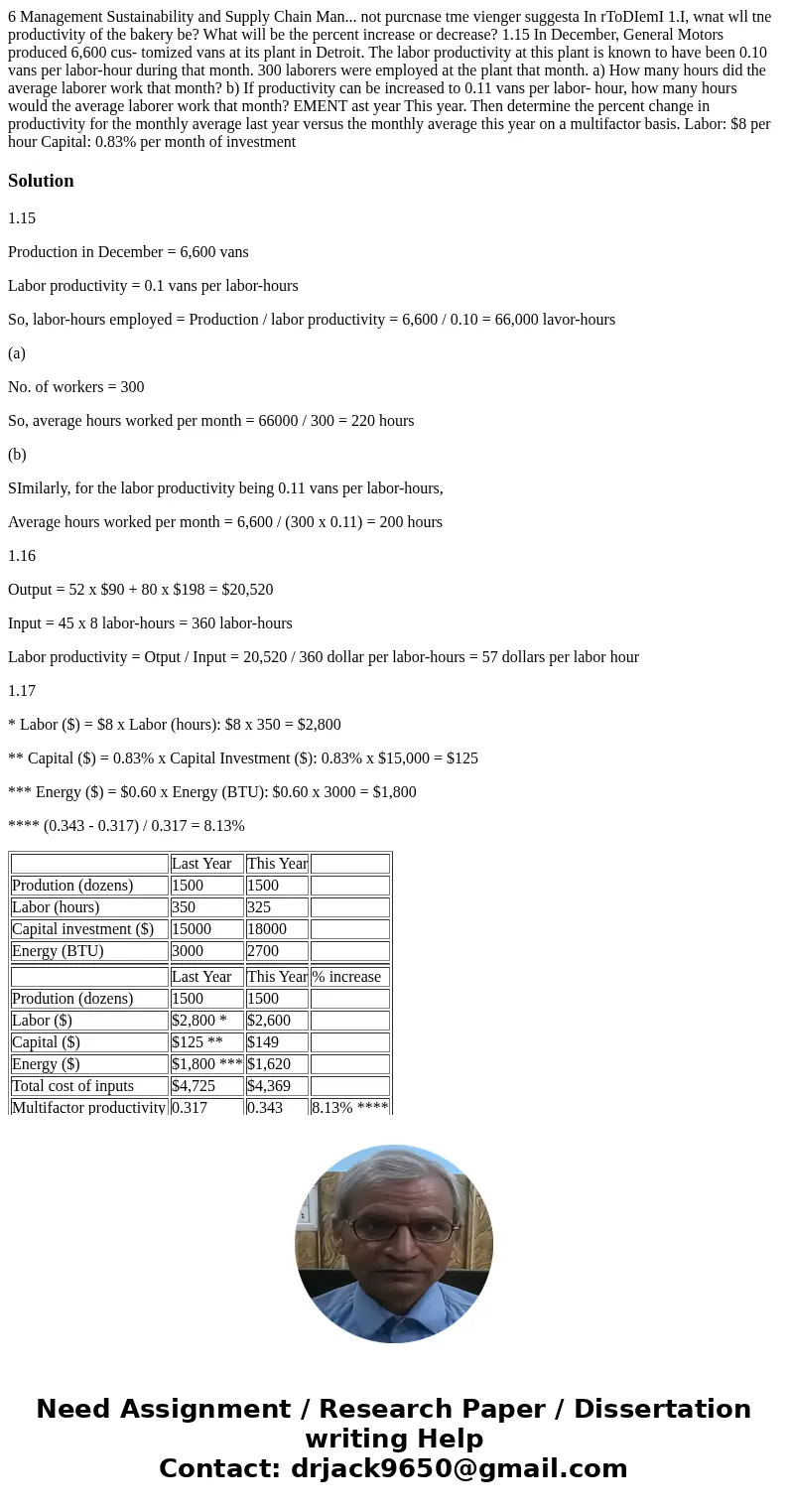

1.17

* Labor ($) = $8 x Labor (hours): $8 x 350 = $2,800

** Capital ($) = 0.83% x Capital Investment ($): 0.83% x $15,000 = $125

*** Energy ($) = $0.60 x Energy (BTU): $0.60 x 3000 = $1,800

**** (0.343 - 0.317) / 0.317 = 8.13%

| Last Year | This Year | ||

| Prodution (dozens) | 1500 | 1500 | |

| Labor (hours) | 350 | 325 | |

| Capital investment ($) | 15000 | 18000 | |

| Energy (BTU) | 3000 | 2700 | |

| Last Year | This Year | % increase | |

| Prodution (dozens) | 1500 | 1500 | |

| Labor ($) | $2,800 * | $2,600 | |

| Capital ($) | $125 ** | $149 | |

| Energy ($) | $1,800 *** | $1,620 | |

| Total cost of inputs | $4,725 | $4,369 | |

| Multifactor productivity | 0.317 | 0.343 | 8.13% **** |

Homework Sourse

Homework Sourse