Process Activity Components Changeover Overhead Cost Driver

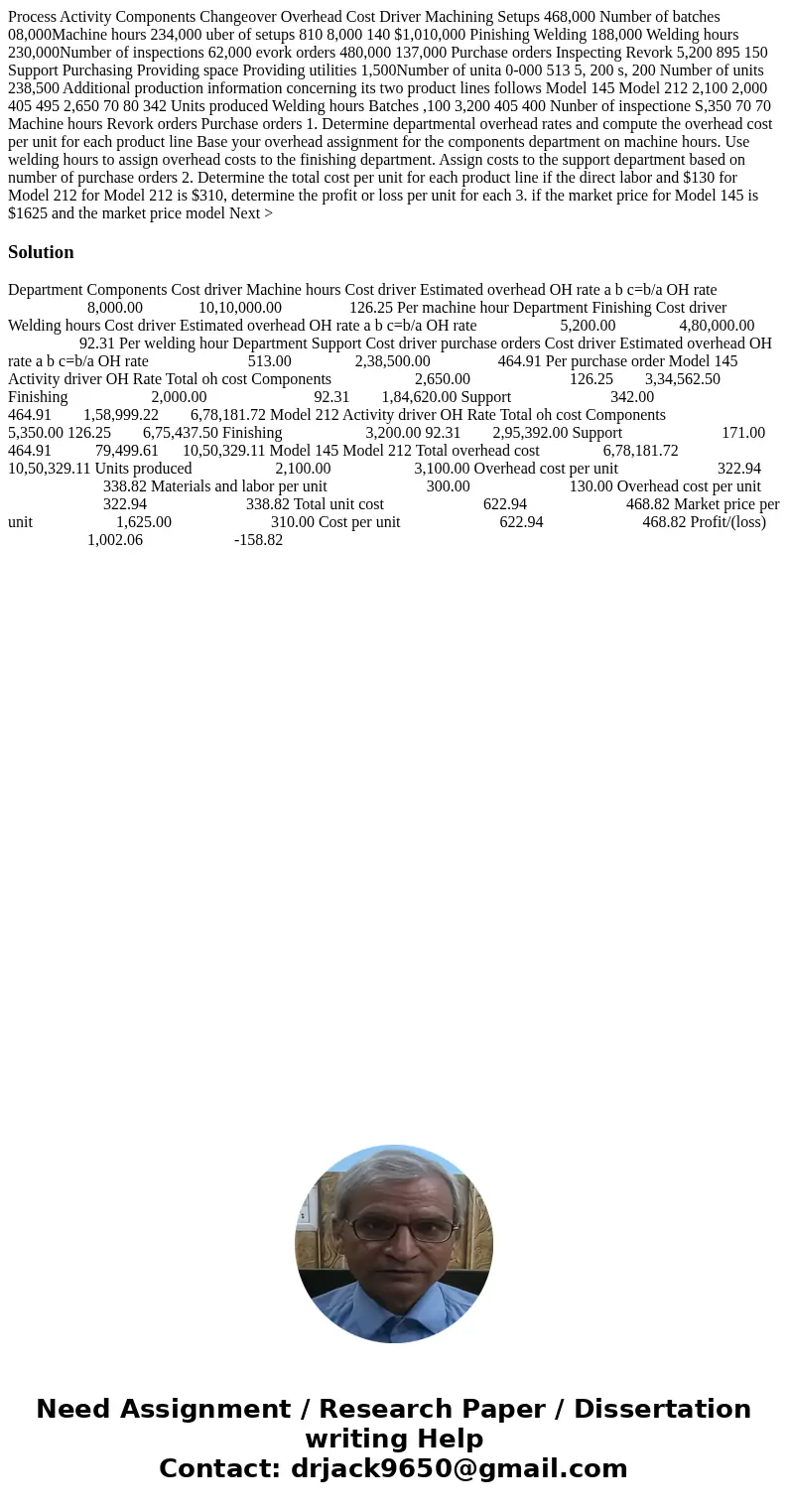

Process Activity Components Changeover Overhead Cost Driver Machining Setups 468,000 Number of batches 08,000Machine hours 234,000 uber of setups 810 8,000 140 $1,010,000 Pinishing Welding 188,000 Welding hours 230,000Number of inspections 62,000 evork orders 480,000 137,000 Purchase orders Inspecting Revork 5,200 895 150 Support Purchasing Providing space Providing utilities 1,500Number of unita 0-000 513 5, 200 s, 200 Number of units 238,500 Additional production information concerning its two product lines follows Model 145 Model 212 2,100 2,000 405 495 2,650 70 80 342 Units produced Welding hours Batches ,100 3,200 405 400 Nunber of inspectione S,350 70 70 Machine hours Revork orders Purchase orders 1. Determine departmental overhead rates and compute the overhead cost per unit for each product line Base your overhead assignment for the components department on machine hours. Use welding hours to assign overhead costs to the finishing department. Assign costs to the support department based on number of purchase orders 2. Determine the total cost per unit for each product line if the direct labor and $130 for Model 212 for Model 212 is $310, determine the profit or loss per unit for each 3. if the market price for Model 145 is $1625 and the market price model Next >

Solution

Department Components Cost driver Machine hours Cost driver Estimated overhead OH rate a b c=b/a OH rate 8,000.00 10,10,000.00 126.25 Per machine hour Department Finishing Cost driver Welding hours Cost driver Estimated overhead OH rate a b c=b/a OH rate 5,200.00 4,80,000.00 92.31 Per welding hour Department Support Cost driver purchase orders Cost driver Estimated overhead OH rate a b c=b/a OH rate 513.00 2,38,500.00 464.91 Per purchase order Model 145 Activity driver OH Rate Total oh cost Components 2,650.00 126.25 3,34,562.50 Finishing 2,000.00 92.31 1,84,620.00 Support 342.00 464.91 1,58,999.22 6,78,181.72 Model 212 Activity driver OH Rate Total oh cost Components 5,350.00 126.25 6,75,437.50 Finishing 3,200.00 92.31 2,95,392.00 Support 171.00 464.91 79,499.61 10,50,329.11 Model 145 Model 212 Total overhead cost 6,78,181.72 10,50,329.11 Units produced 2,100.00 3,100.00 Overhead cost per unit 322.94 338.82 Materials and labor per unit 300.00 130.00 Overhead cost per unit 322.94 338.82 Total unit cost 622.94 468.82 Market price per unit 1,625.00 310.00 Cost per unit 622.94 468.82 Profit/(loss) 1,002.06 -158.82

Homework Sourse

Homework Sourse