Twelve tasks, with times and precedence requirements as shown in the following table, are to be assigned to workstations that have a fixed machine cycle time of 1.5 minutes. Two rules will be tried: greatest potential weight, and greatest number of following tasks. In each case the tie breaker will be shortest task time. Assign tasks to stations under each of the two rules. greatest positional weight greatest number of following tasks

Anwer:

Assembly Line Balancing Table (CT = 1.5 minutes)

Work Station

Task

Task Time

Time Remaining

Feasible tasks Remaining

I

A

0.1

1.4

B

B

0.2

1.2

C

C

0.9

0.3

E

E

0.1

0.2

–

II

D

0.6

0.9

F

F

0.2

0.7

G

G

0.4

0.3

H

H

0.1

0.2

I

I

0.2

–

–

III

J

0.7

0.8

K

K

0.3

0.5

L

L

0.2

0.3

–

Total idle time = 0.2 + 0 + 0.3 = 0.5

c. For positional weights and greatest number of following tasks

|

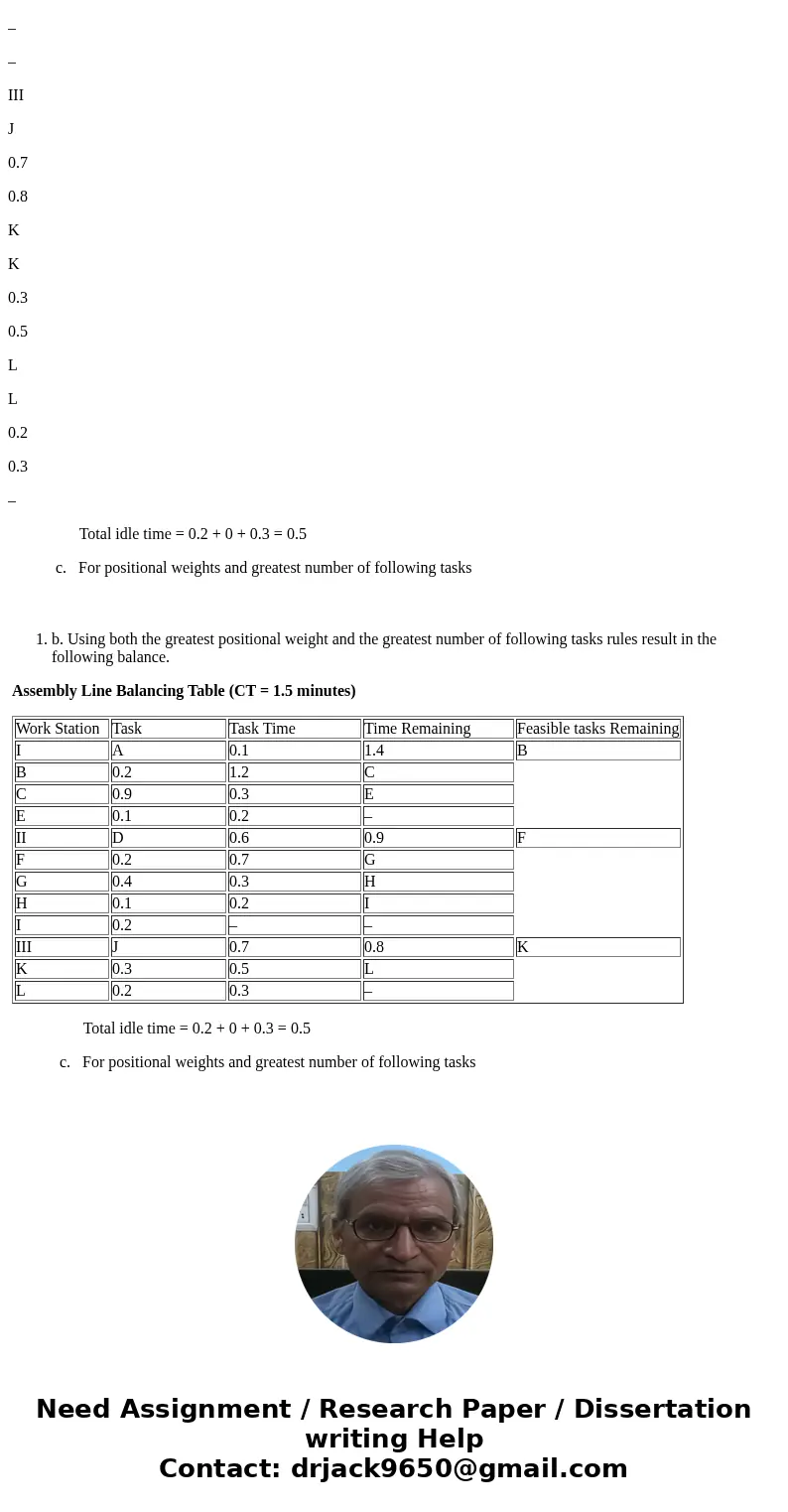

| - b. Using both the greatest positional weight and the greatest number of following tasks rules result in the following balance.

Assembly Line Balancing Table (CT = 1.5 minutes) | Work Station | Task | Task Time | Time Remaining | Feasible tasks Remaining | | I | A | 0.1 | 1.4 | B | | B | 0.2 | 1.2 | C | | C | 0.9 | 0.3 | E | | E | 0.1 | 0.2 | – | | II | D | 0.6 | 0.9 | F | | F | 0.2 | 0.7 | G | | G | 0.4 | 0.3 | H | | H | 0.1 | 0.2 | I | | I | 0.2 | – | – | | III | J | 0.7 | 0.8 | K | | K | 0.3 | 0.5 | L | | L | 0.2 | 0.3 | – | Total idle time = 0.2 + 0 + 0.3 = 0.5 c. For positional weights and greatest number of following tasks |

Homework Sourse

Homework Sourse