Problem 116 Manager Chris Channing of Fabric Mills Inc has d

Problem 11-6

Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a normal capacity of 275(00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be assigned to other jobs if production is less than normal. The beginning inventory is zero bolts.

Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter \"0\" wherever required. Omit the \"$\" sign in your response.)

Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above normal capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts. (Round your Average values to 1 decimal place. Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter \"0\" wherever required. Omit the \"$\" sign in your response.)

| Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown in the table for bolts of cloth. The figures are in hundreds of bolts. The department has a normal capacity of 275(00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be assigned to other jobs if production is less than normal. The beginning inventory is zero bolts. |

Solution

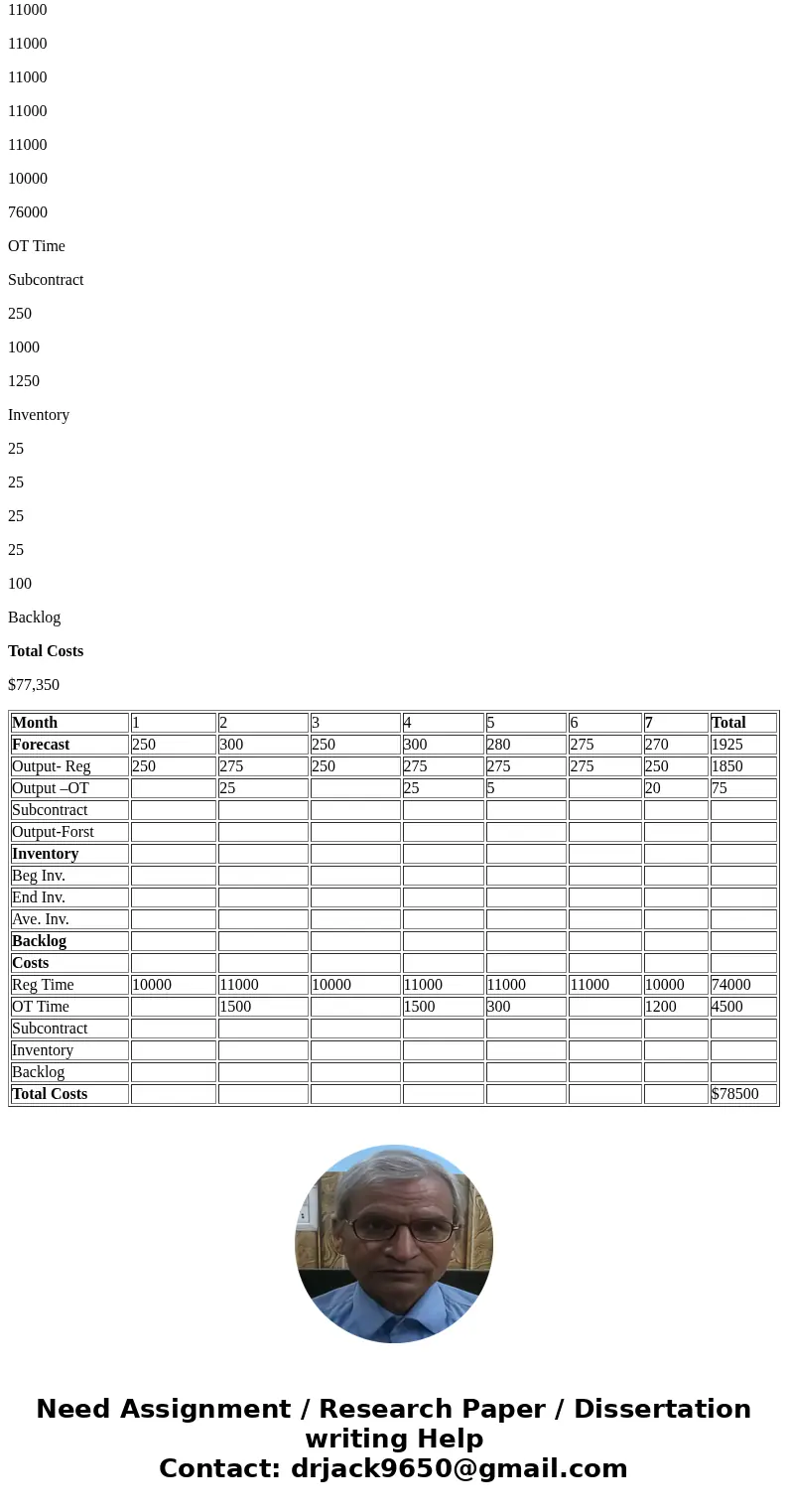

A.)

Month

1

2

3

4

5

6

7

Total

Forecast

250

300

250

300

280

275

270

1925

Output- Reg

250

275

250

275

275

275

250

1850

Output –OT

25

25

5

20

75

Subcontract

Output-Forst

Inventory

Beg Inv.

End Inv.

Ave. Inv.

Backlog

Costs

Reg Time

10000

11000

10000

11000

11000

11000

10000

74000

OT Time

1500

1500

300

1200

4500

Subcontract

Inventory

Backlog

Total Costs

$78500

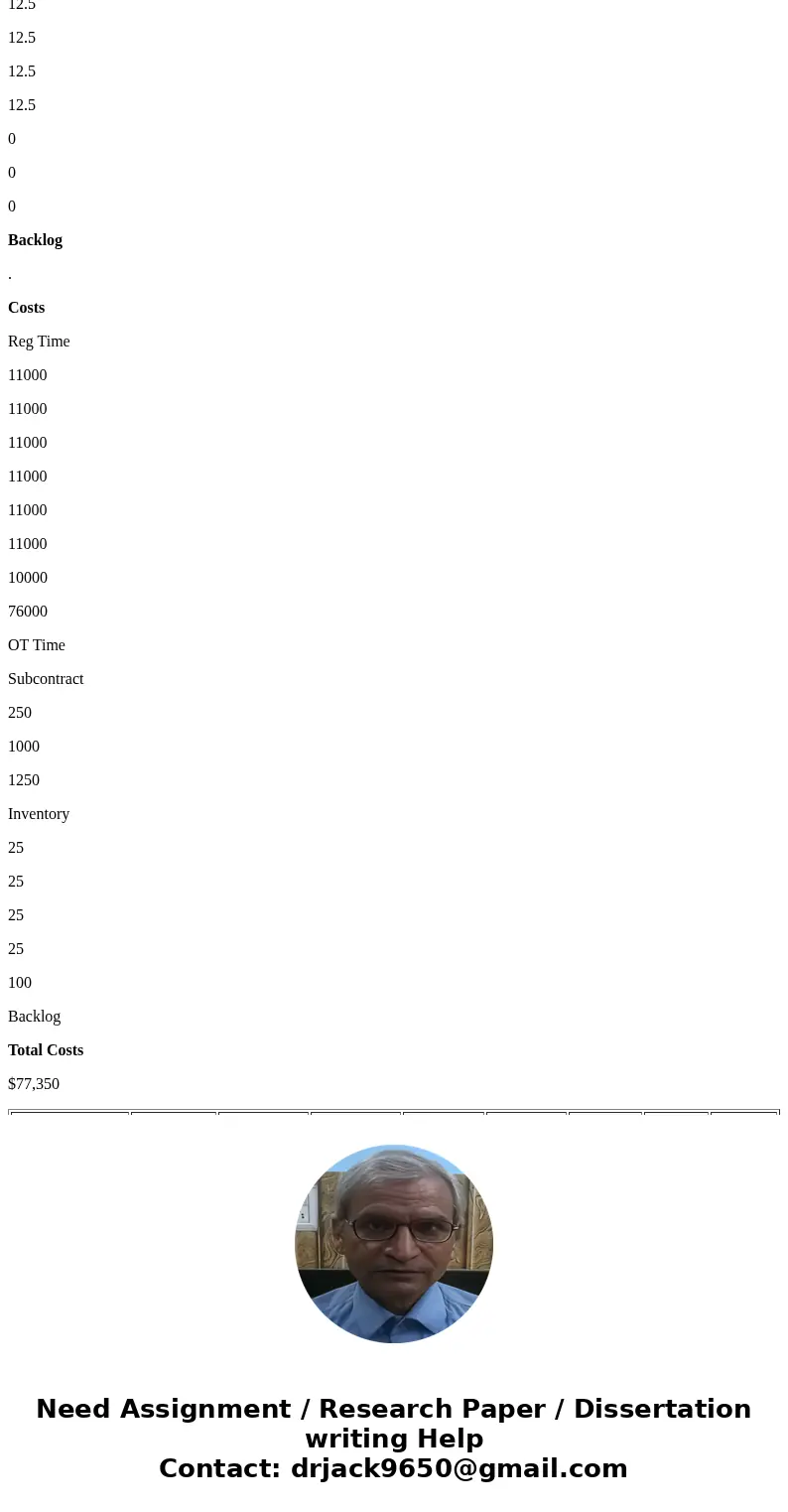

B.)

Month

1

2

3

4

5

6

7

Total

Forecast

250

300

250

300

280

275

270

1925

Output- Reg

275

275

275

275

275

275

250

Output –OT

Subcontract

5

20

Output-Forst

25

-25

25

-25

-5

0

-20

Inventory

Beg Inv.

0

25

0

25

0

0

0

End Inv.

25

0

25

0

0

0

0

Ave. Inv.

12.5

12.5

12.5

12.5

0

0

0

Backlog

.

Costs

Reg Time

11000

11000

11000

11000

11000

11000

10000

76000

OT Time

Subcontract

250

1000

1250

Inventory

25

25

25

25

100

Backlog

Total Costs

$77,350

| Month | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Total |

| Forecast | 250 | 300 | 250 | 300 | 280 | 275 | 270 | 1925 |

| Output- Reg | 250 | 275 | 250 | 275 | 275 | 275 | 250 | 1850 |

| Output –OT | 25 | 25 | 5 | 20 | 75 | |||

| Subcontract | ||||||||

| Output-Forst | ||||||||

| Inventory | ||||||||

| Beg Inv. | ||||||||

| End Inv. | ||||||||

| Ave. Inv. | ||||||||

| Backlog | ||||||||

| Costs | ||||||||

| Reg Time | 10000 | 11000 | 10000 | 11000 | 11000 | 11000 | 10000 | 74000 |

| OT Time | 1500 | 1500 | 300 | 1200 | 4500 | |||

| Subcontract | ||||||||

| Inventory | ||||||||

| Backlog | ||||||||

| Total Costs | $78500 |

Homework Sourse

Homework Sourse