TABLE 1814ii Values in microns Tolerances of holes Tolerance

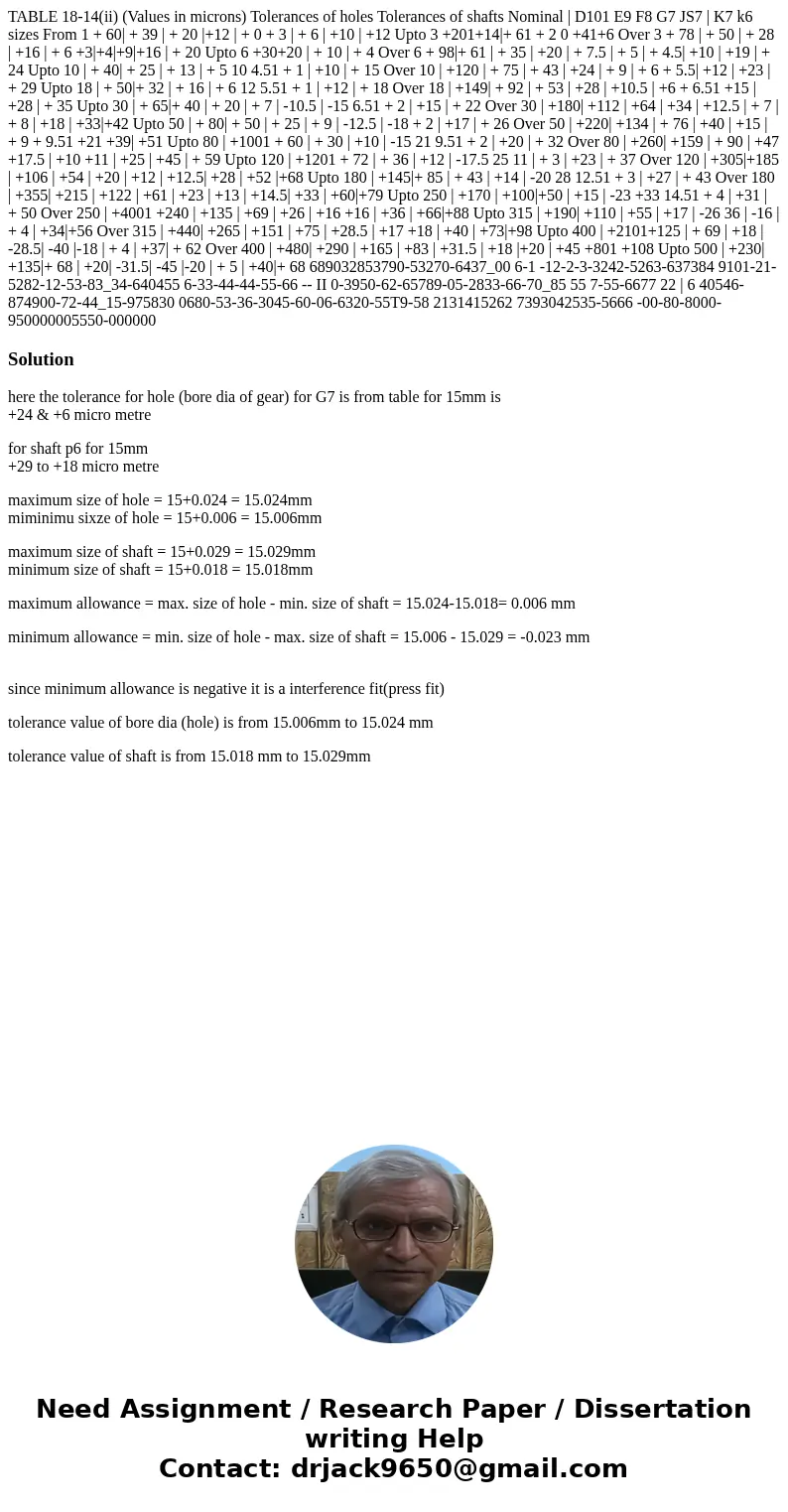

TABLE 18-14(ii) (Values in microns) Tolerances of holes Tolerances of shafts Nominal | D101 E9 F8 G7 JS7 | K7 k6 sizes From 1 + 60| + 39 | + 20 |+12 | + 0 + 3 | + 6 | +10 | +12 Upto 3 +201+14|+ 61 + 2 0 +41+6 Over 3 + 78 | + 50 | + 28 | +16 | + 6 +3|+4|+9|+16 | + 20 Upto 6 +30+20 | + 10 | + 4 Over 6 + 98|+ 61 | + 35 | +20 | + 7.5 | + 5 | + 4.5| +10 | +19 | + 24 Upto 10 | + 40| + 25 | + 13 | + 5 10 4.51 + 1 | +10 | + 15 Over 10 | +120 | + 75 | + 43 | +24 | + 9 | + 6 + 5.5| +12 | +23 | + 29 Upto 18 | + 50|+ 32 | + 16 | + 6 12 5.51 + 1 | +12 | + 18 Over 18 | +149| + 92 | + 53 | +28 | +10.5 | +6 + 6.51 +15 | +28 | + 35 Upto 30 | + 65|+ 40 | + 20 | + 7 | -10.5 | -15 6.51 + 2 | +15 | + 22 Over 30 | +180| +112 | +64 | +34 | +12.5 | + 7 | + 8 | +18 | +33|+42 Upto 50 | + 80| + 50 | + 25 | + 9 | -12.5 | -18 + 2 | +17 | + 26 Over 50 | +220| +134 | + 76 | +40 | +15 | + 9 + 9.51 +21 +39| +51 Upto 80 | +1001 + 60 | + 30 | +10 | -15 21 9.51 + 2 | +20 | + 32 Over 80 | +260| +159 | + 90 | +47 +17.5 | +10 +11 | +25 | +45 | + 59 Upto 120 | +1201 + 72 | + 36 | +12 | -17.5 25 11 | + 3 | +23 | + 37 Over 120 | +305|+185 | +106 | +54 | +20 | +12 | +12.5| +28 | +52 |+68 Upto 180 | +145|+ 85 | + 43 | +14 | -20 28 12.51 + 3 | +27 | + 43 Over 180 | +355| +215 | +122 | +61 | +23 | +13 | +14.5| +33 | +60|+79 Upto 250 | +170 | +100|+50 | +15 | -23 +33 14.51 + 4 | +31 | + 50 Over 250 | +4001 +240 | +135 | +69 | +26 | +16 +16 | +36 | +66|+88 Upto 315 | +190| +110 | +55 | +17 | -26 36 | -16 | + 4 | +34|+56 Over 315 | +440| +265 | +151 | +75 | +28.5 | +17 +18 | +40 | +73|+98 Upto 400 | +2101+125 | + 69 | +18 | -28.5| -40 |-18 | + 4 | +37| + 62 Over 400 | +480| +290 | +165 | +83 | +31.5 | +18 |+20 | +45 +801 +108 Upto 500 | +230| +135|+ 68 | +20| -31.5| -45 |-20 | + 5 | +40|+ 68 689032853790-53270-6437_00 6-1 -12-2-3-3242-5263-637384 9101-21-5282-12-53-83_34-640455 6-33-44-44-55-66 -- II 0-3950-62-65789-05-2833-66-70_85 55 7-55-6677 22 | 6 40546-874900-72-44_15-975830 0680-53-36-3045-60-06-6320-55T9-58 2131415262 7393042535-5666 -00-80-8000-950000005550-000000

Solution

here the tolerance for hole (bore dia of gear) for G7 is from table for 15mm is

+24 & +6 micro metre

for shaft p6 for 15mm

+29 to +18 micro metre

maximum size of hole = 15+0.024 = 15.024mm

miminimu sixze of hole = 15+0.006 = 15.006mm

maximum size of shaft = 15+0.029 = 15.029mm

minimum size of shaft = 15+0.018 = 15.018mm

maximum allowance = max. size of hole - min. size of shaft = 15.024-15.018= 0.006 mm

minimum allowance = min. size of hole - max. size of shaft = 15.006 - 15.029 = -0.023 mm

since minimum allowance is negative it is a interference fit(press fit)

tolerance value of bore dia (hole) is from 15.006mm to 15.024 mm

tolerance value of shaft is from 15.018 mm to 15.029mm

Homework Sourse

Homework Sourse