Because of its labor contract a company must hire enough lab

Solution

Total production required = Ending inventory + sum of forecast demand – Opening inventory = 300 + 1080 – 200 = 1180

Since week 2 is cut to half, total number of weeks available for production = 5.5 weeks

It is however mentioned that maximum available normal monthly production = 200

Thus, total normal production in 5.5 weeks = 200 x 5.5 = 1100 units

Thus , shortfall which needs to be catered from extra production during week 4 = 1180 – 1100 = 80 units

It is to be note that maximum “upto 100 units” can be produced in week 4 .

Since production requirement of 80 < Maximum additional production available of 100 units, it is a feasible plan

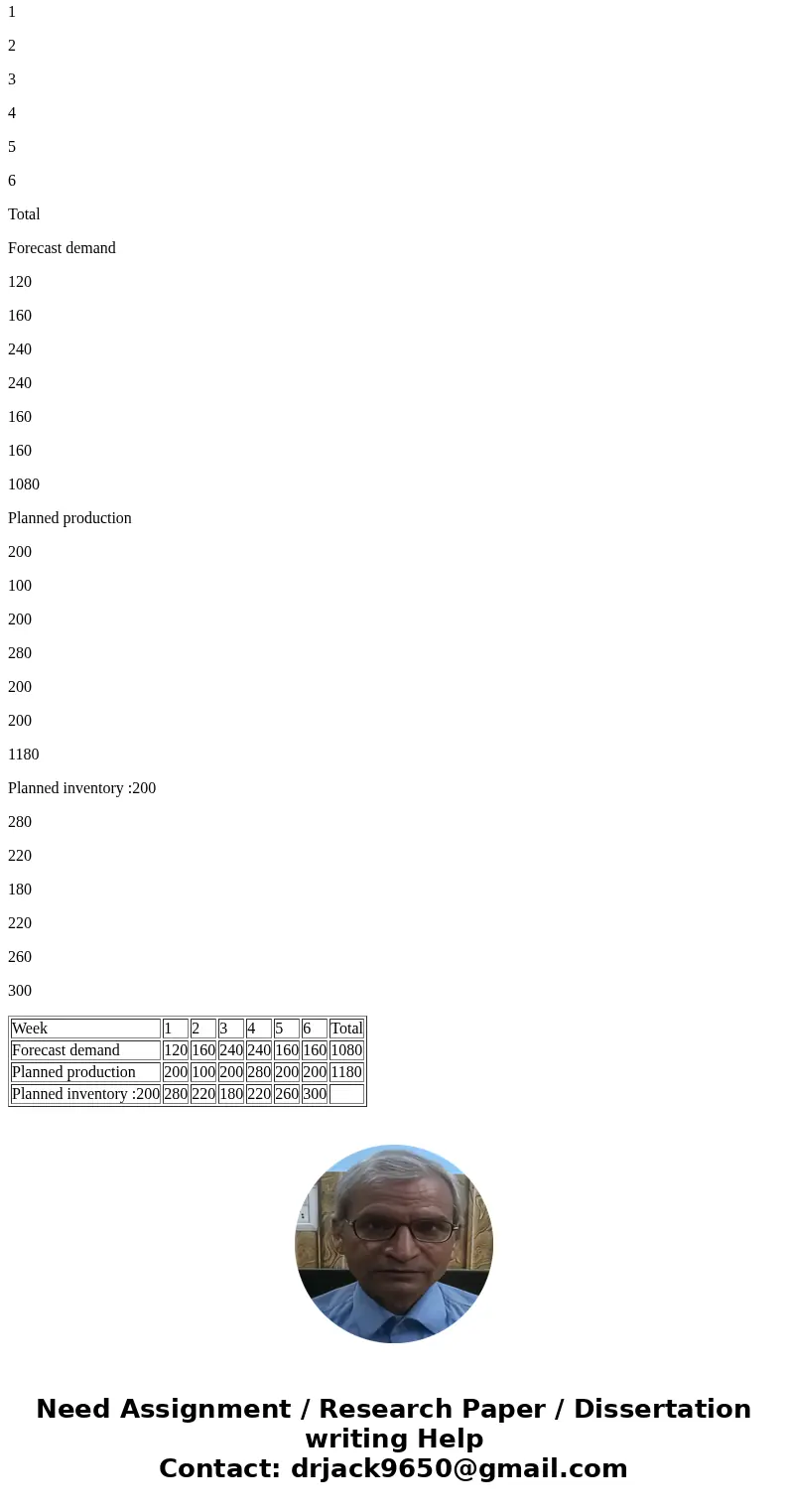

Thus Production plan would be as per following:

Week 1 = 200 units

Week 2 = 100 units

Week 3 = 200 Units

Week 4 = 200 + 80 = 280units

Week 5 = 200 units

Week 6 = 200 units

Week

1

2

3

4

5

6

Total

Forecast demand

120

160

240

240

160

160

1080

Planned production

200

100

200

280

200

200

1180

Planned inventory :200

280

220

180

220

260

300

| Week | 1 | 2 | 3 | 4 | 5 | 6 | Total |

| Forecast demand | 120 | 160 | 240 | 240 | 160 | 160 | 1080 |

| Planned production | 200 | 100 | 200 | 280 | 200 | 200 | 1180 |

| Planned inventory :200 | 280 | 220 | 180 | 220 | 260 | 300 |

Homework Sourse

Homework Sourse