Saddle Inc has two types of handbags standard and custom The

Solution

(a) Overhead rate using the traditional (plant wide) approach

Overhead rate = Total estimated overhead costs / Direct labor costs

= $297,000 / [ $59,000 + 119,000 ]

= $297,000 / 178,000

= 166.85% of Direct Labor Cost

Predetermined Overhead Rate = 166.85% of Direct Labor Cost

(b) Overhead rates using the activity-based costing approach

Machining Activity = $79.05 per machine hours

Machine setup = $190.94 per set up hours

Machining Activity

= Overhead cost allocated to the machining activity cost pool / Total Machine Hours

= $200,000 / [ 1350 Machine hours + 1180 Machine Hours ]

= $200,000 / 2530 Machine Hours

= $79.05 per machine hours

Machine setup

= Overhead cost allocated to the machining activity cost pool / Total Set up hours

= $97,000 / [ 98 set up hours + 410 set up hours ]

= $97,000 / 508 Set up hours

= $190.94 per set up hours

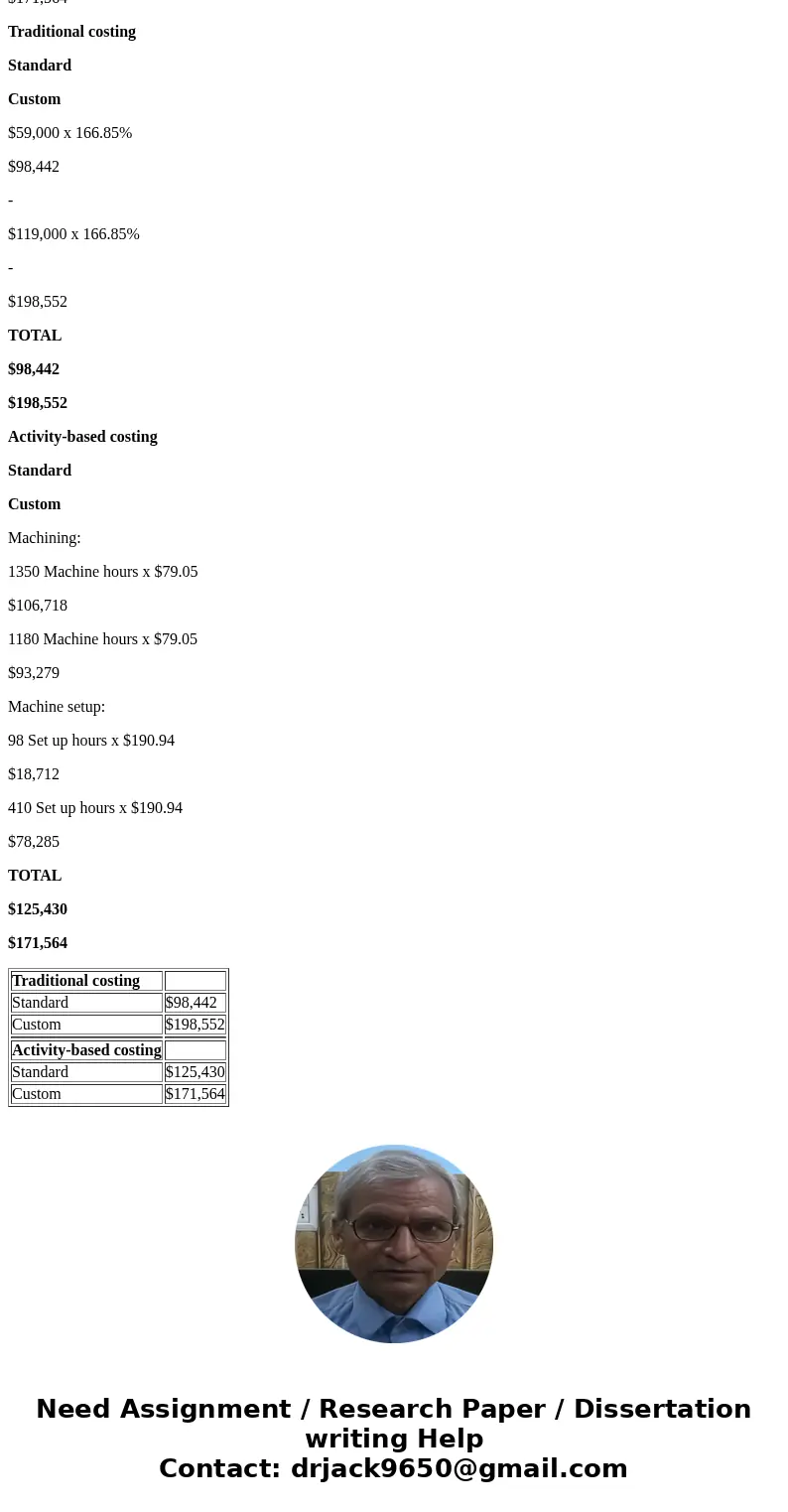

(c) Difference in allocation between the two approaches

Traditional costing

Standard

$98,442

Custom

$198,552

Activity-based costing

Standard

$125,430

Custom

$171,564

Traditional costing

Standard

Custom

$59,000 x 166.85%

$98,442

-

$119,000 x 166.85%

-

$198,552

TOTAL

$98,442

$198,552

Activity-based costing

Standard

Custom

Machining:

1350 Machine hours x $79.05

$106,718

1180 Machine hours x $79.05

$93,279

Machine setup:

98 Set up hours x $190.94

$18,712

410 Set up hours x $190.94

$78,285

TOTAL

$125,430

$171,564

| Traditional costing | |

| Standard | $98,442 |

| Custom | $198,552 |

| Activity-based costing | |

| Standard | $125,430 |

| Custom | $171,564 |

Homework Sourse

Homework Sourse