The cost of producing each unit is 1000 on regular time 1200

The cost of producing each unit is $1,000 on regular time, $1,200 on overtime, and $1,800 on a subcontract. Inventory carrying cost is $200 per unit per month. There is no beginning or ending inventory in stock, and no backorders are permitted from period to period. Let the workforce vary by using regular time first, then overtime, and then subcontracting. This plan allows no backorders or inventory. Minimizing cost by producing exactly what the demand is each month, the total cost is $ 2625600 (enter your response as a whole number). Through better planning regular-time production can be set at exactly the same amount, 270 units, per month. Let the workforce vary by using regular time first, Then overtime, and then subcontracting. If demand cannot be met, there is no cost assigned to shortages and they will not be filled. This paln\'s total cost is $ (enter your response as a whole number).

Solution

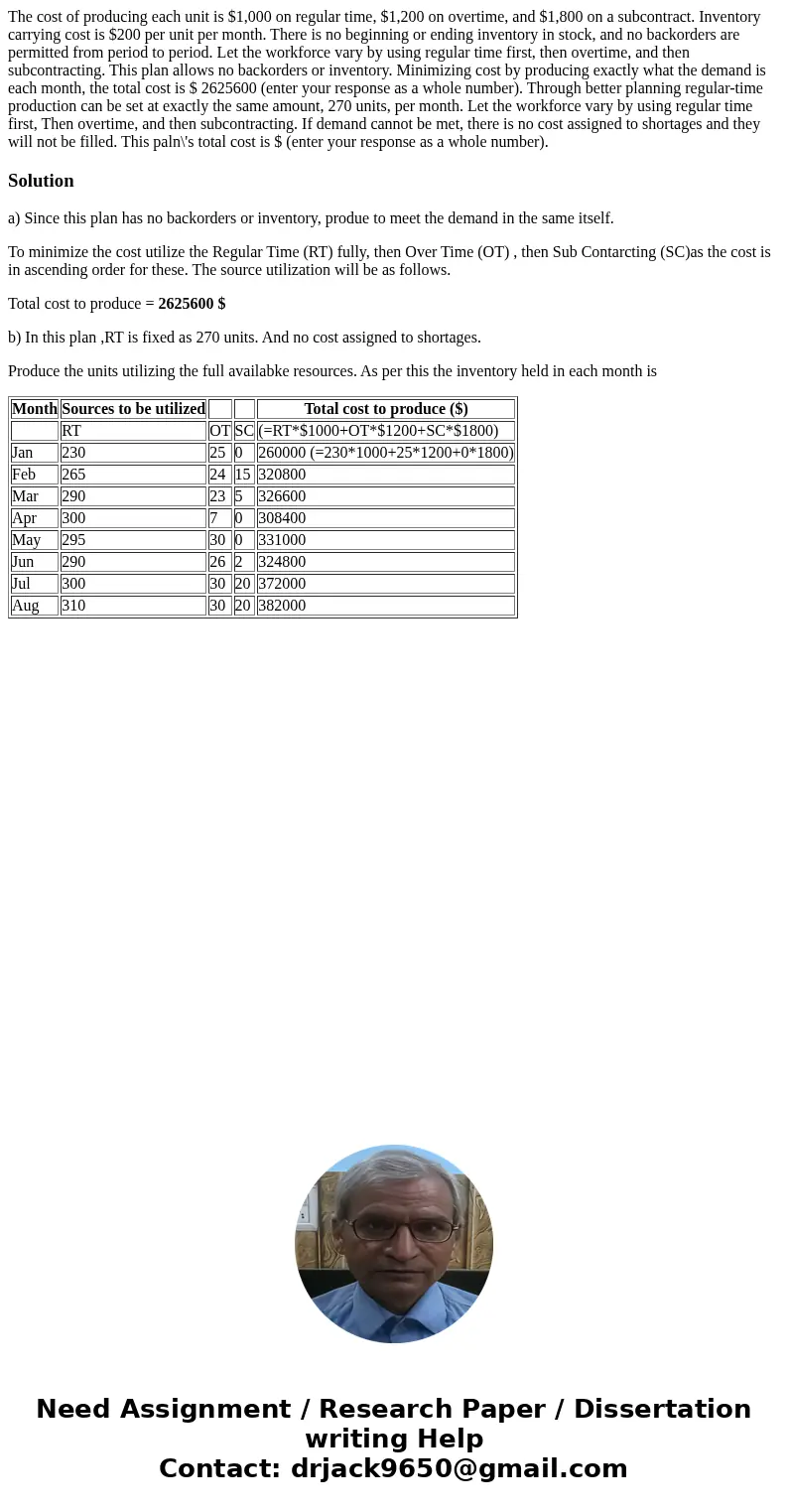

a) Since this plan has no backorders or inventory, produe to meet the demand in the same itself.

To minimize the cost utilize the Regular Time (RT) fully, then Over Time (OT) , then Sub Contarcting (SC)as the cost is in ascending order for these. The source utilization will be as follows.

Total cost to produce = 2625600 $

b) In this plan ,RT is fixed as 270 units. And no cost assigned to shortages.

Produce the units utilizing the full availabke resources. As per this the inventory held in each month is

| Month | Sources to be utilized | Total cost to produce ($) | ||

|---|---|---|---|---|

| RT | OT | SC | (=RT*$1000+OT*$1200+SC*$1800) | |

| Jan | 230 | 25 | 0 | 260000 (=230*1000+25*1200+0*1800) |

| Feb | 265 | 24 | 15 | 320800 |

| Mar | 290 | 23 | 5 | 326600 |

| Apr | 300 | 7 | 0 | 308400 |

| May | 295 | 30 | 0 | 331000 |

| Jun | 290 | 26 | 2 | 324800 |

| Jul | 300 | 30 | 20 | 372000 |

| Aug | 310 | 30 | 20 | 382000 |

Homework Sourse

Homework Sourse