One ball bearing was measured by one inspector 13 times with

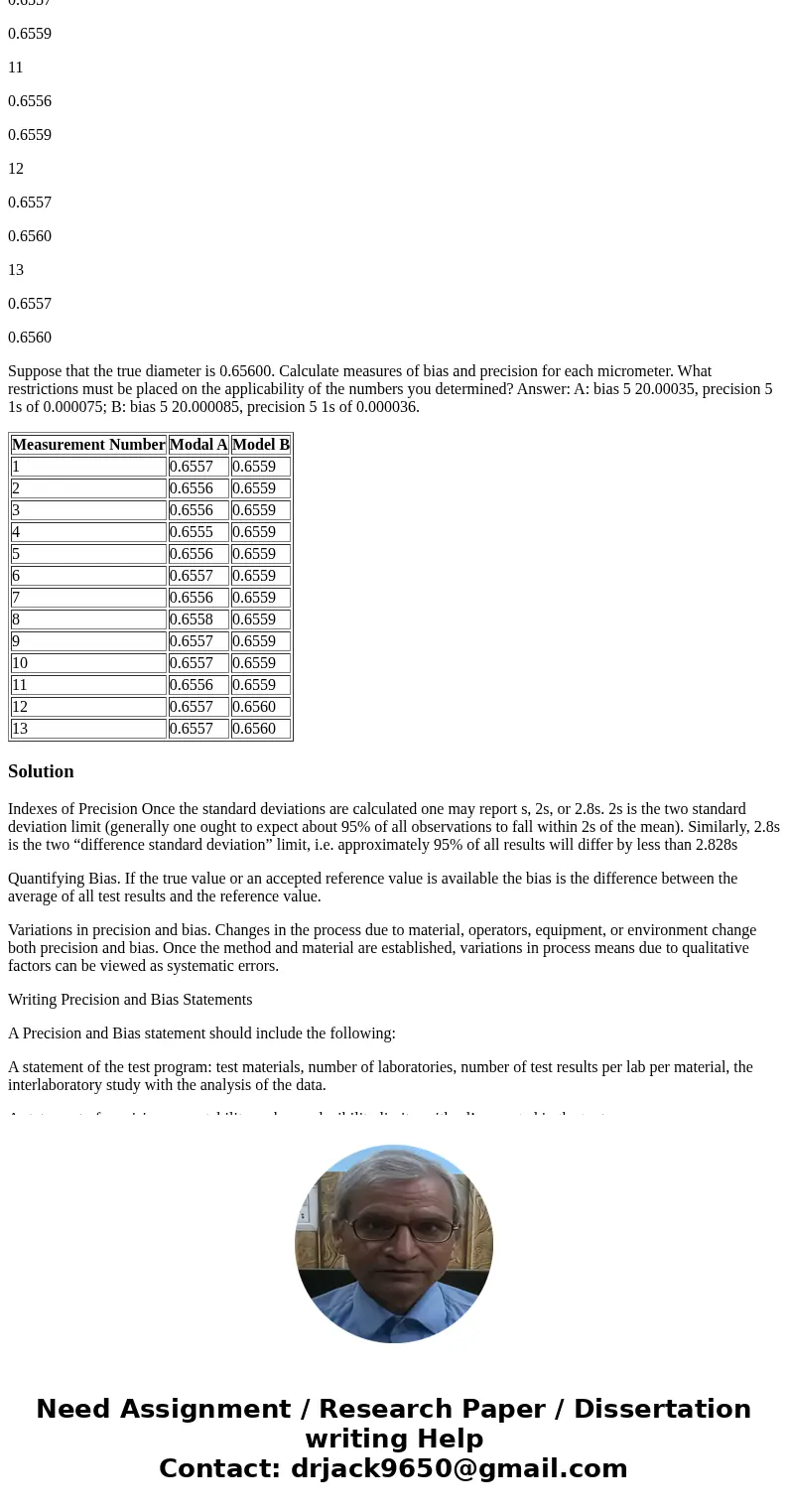

One ball bearing was measured by one inspector 13 times with each of two Vernier micrometers. The results are shown here:

Measurement Number

Modal A

Model B

1

0.6557

0.6559

2

0.6556

0.6559

3

0.6556

0.6559

4

0.6555

0.6559

5

0.6556

0.6559

6

0.6557

0.6559

7

0.6556

0.6559

8

0.6558

0.6559

9

0.6557

0.6559

10

0.6557

0.6559

11

0.6556

0.6559

12

0.6557

0.6560

13

0.6557

0.6560

Suppose that the true diameter is 0.65600. Calculate measures of bias and precision for each micrometer. What restrictions must be placed on the applicability of the numbers you determined? Answer: A: bias 5 20.00035, precision 5 1s of 0.000075; B: bias 5 20.000085, precision 5 1s of 0.000036.

| Measurement Number | Modal A | Model B |

| 1 | 0.6557 | 0.6559 |

| 2 | 0.6556 | 0.6559 |

| 3 | 0.6556 | 0.6559 |

| 4 | 0.6555 | 0.6559 |

| 5 | 0.6556 | 0.6559 |

| 6 | 0.6557 | 0.6559 |

| 7 | 0.6556 | 0.6559 |

| 8 | 0.6558 | 0.6559 |

| 9 | 0.6557 | 0.6559 |

| 10 | 0.6557 | 0.6559 |

| 11 | 0.6556 | 0.6559 |

| 12 | 0.6557 | 0.6560 |

| 13 | 0.6557 | 0.6560 |

Solution

Indexes of Precision Once the standard deviations are calculated one may report s, 2s, or 2.8s. 2s is the two standard deviation limit (generally one ought to expect about 95% of all observations to fall within 2s of the mean). Similarly, 2.8s is the two “difference standard deviation” limit, i.e. approximately 95% of all results will differ by less than 2.828s

Quantifying Bias. If the true value or an accepted reference value is available the bias is the difference between the average of all test results and the reference value.

Variations in precision and bias. Changes in the process due to material, operators, equipment, or environment change both precision and bias. Once the method and material are established, variations in process means due to qualitative factors can be viewed as systematic errors.

Writing Precision and Bias Statements

A Precision and Bias statement should include the following:

A statement of the test program: test materials, number of laboratories, number of test results per lab per material, the interlaboratory study with the analysis of the data.

A statement of precision: repeatability and reproducibility limits, with sd’s reported in the text.

A description of and data from additional studies

A statement about bias:

effects of changing properties on results,

theoretical considerations for contributions to bias,

estimates of maximum amount of bias.

Homework Sourse

Homework Sourse