Issign overhead using E517 LO12Elle Inc makes two types of h

Solution

(a) Overhead rate using the traditional (plant wide) approach

Overhead rate = Total estimated overhead costs / Direct labor costs

= $277,500 / [ $50,000 + 100,000 ]

= $277,500 / 150,000

= 185% of direct labor cost

(b)Overhead rates using the activity-based costing approach

Activity-based overhead rates

Machining Activity

= Overhead cost allocated to the machining activity cost pool / Total Machine Hours

= $177,000 / [ 500 Machine hours + 1000 Machine Hours ]

= $177,000 / 1,500 Machine Hours

= $118 per machine hours

Machine setup

= Overhead cost allocated to the machining activity cost pool / Total Set up hours

= $100,500 / [ 100 set up hours + 400 set up hours ]

= $100,500 / 500 Set up hours

= $201 per set up hours

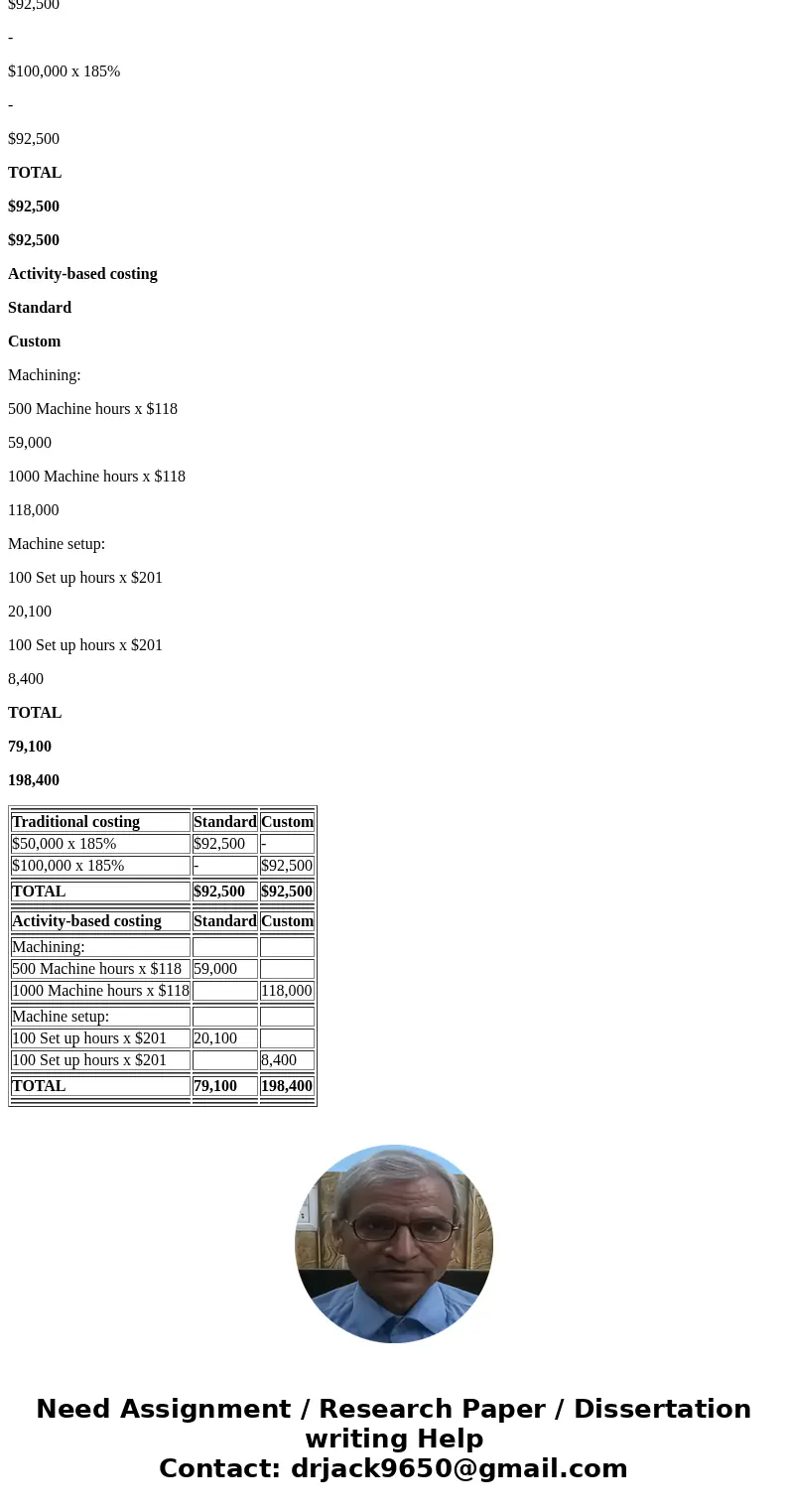

(c) Difference in allocation between the two approaches

Traditional costing

Standard

Custom

$50,000 x 185%

$92,500

-

$100,000 x 185%

-

$92,500

TOTAL

$92,500

$92,500

Activity-based costing

Standard

Custom

Machining:

500 Machine hours x $118

59,000

1000 Machine hours x $118

118,000

Machine setup:

100 Set up hours x $201

20,100

100 Set up hours x $201

8,400

TOTAL

79,100

198,400

| Traditional costing | Standard | Custom |

| $50,000 x 185% | $92,500 | - |

| $100,000 x 185% | - | $92,500 |

| TOTAL | $92,500 | $92,500 |

| Activity-based costing | Standard | Custom |

| Machining: | ||

| 500 Machine hours x $118 | 59,000 | |

| 1000 Machine hours x $118 | 118,000 | |

| Machine setup: | ||

| 100 Set up hours x $201 | 20,100 | |

| 100 Set up hours x $201 | 8,400 | |

| TOTAL | 79,100 | 198,400 |

Homework Sourse

Homework Sourse