Description and costs are listed together Quality training

Description and costs are listed together.

Quality training $ 4,000

Reliability training $ 20,000

Scrap $ 15,000

Downtime $ 6,000

Transportation losses due to shipment delays $ 8,000

Supplies inspection $ 6,000

Contracted performance testing $ 300,000

Pilot production runs $ 8,000

Reliability testing $ 9,560

Based on the following costs, what is the Cost of Quality (CoQ)? (Note, not all of the costs listed in the table are quality costs). Group the costs into one of the four categories associated with the CoQ (prevention, appraisal, internal failure, external failure). Which of the CoQ cost categories is the highest? Which is the lowest?

Solution

Cost of quality is a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality, that appraise the quality of the organization’s products or services, and that result from internal and external failures. Having such information allows an organization to determine the potential savings to be gained by implementing process improvements.

Quality-related activities that incur costs may be divided into prevention costs, appraisal costs, and internal and external failure costs.

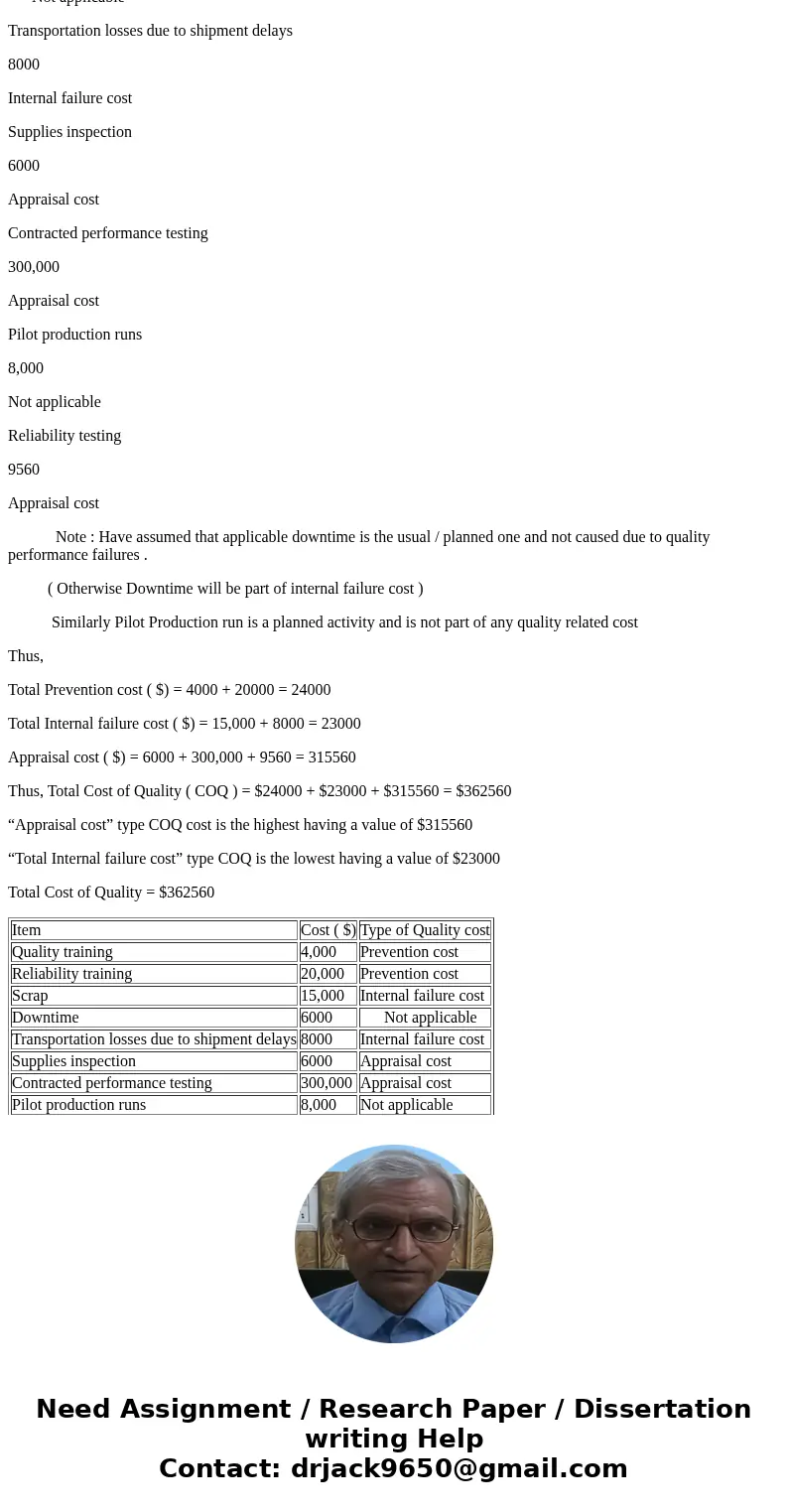

The various activities have been categorized accordingly.

Item

Cost ( $)

Type of Quality cost

Quality training

4,000

Prevention cost

Reliability training

20,000

Prevention cost

Scrap

15,000

Internal failure cost

Downtime

6000

Not applicable

Transportation losses due to shipment delays

8000

Internal failure cost

Supplies inspection

6000

Appraisal cost

Contracted performance testing

300,000

Appraisal cost

Pilot production runs

8,000

Not applicable

Reliability testing

9560

Appraisal cost

Note : Have assumed that applicable downtime is the usual / planned one and not caused due to quality performance failures .

( Otherwise Downtime will be part of internal failure cost )

Similarly Pilot Production run is a planned activity and is not part of any quality related cost

Thus,

Total Prevention cost ( $) = 4000 + 20000 = 24000

Total Internal failure cost ( $) = 15,000 + 8000 = 23000

Appraisal cost ( $) = 6000 + 300,000 + 9560 = 315560

Thus, Total Cost of Quality ( COQ ) = $24000 + $23000 + $315560 = $362560

“Appraisal cost” type COQ cost is the highest having a value of $315560

“Total Internal failure cost” type COQ is the lowest having a value of $23000

Total Cost of Quality = $362560

| Item | Cost ( $) | Type of Quality cost |

| Quality training | 4,000 | Prevention cost |

| Reliability training | 20,000 | Prevention cost |

| Scrap | 15,000 | Internal failure cost |

| Downtime | 6000 | Not applicable |

| Transportation losses due to shipment delays | 8000 | Internal failure cost |

| Supplies inspection | 6000 | Appraisal cost |

| Contracted performance testing | 300,000 | Appraisal cost |

| Pilot production runs | 8,000 | Not applicable |

| Reliability testing | 9560 | Appraisal cost |

Homework Sourse

Homework Sourse