The transducer in the picture has a special Plexiglas wedge

The transducer in the picture has a special Plexiglas wedge that can modify the angle of incidence of the wave. Assuming the transducer generates longitudinal waves, consider that you are asked to inspect two different plates to look for surface defects. The properties of the wedge are the following: Plexiglass vL = 2.67km/sec; vS = 1.12km/sec The mechanical properties of the steel plate are the following: E=200GPa, v=0.29, density = 7800kg/m^3. The mechanical properties of the aluminum plate are the following: E=69GPa, v=0.3 (Poisson ratio), material density = 2700kg/m^3. What waves would you ideally generate to detect surface defects and why? What angle of incidence of the longitudinal wave generated by the transducer would you use for the aluminum and steel plate

Solution

Ideally in a longitudinal waves, the particles travel in the same direction as the incident waves. Incase of the shear waves, the particles travel perpendicular to the incident waves. A general rule of thumb is that the discontinuity must be larger than one half the wavelength to stand a reasonable chance of being detected.

In this case I would use a longitudinal waves along with an angle, so as to ensure we do not miss out on any minor cracks.

According to snell\'s law VL1/VL2=Sin(teta1)/sin(teta2)

Where VL1 is the velocity of incident wave and VL2 is the velocity of the reflected wave.

The difference between the incident and the reflected wave is less when teta is 90 degree (Maximum). such that Vl1=Vl2 (Ideally)

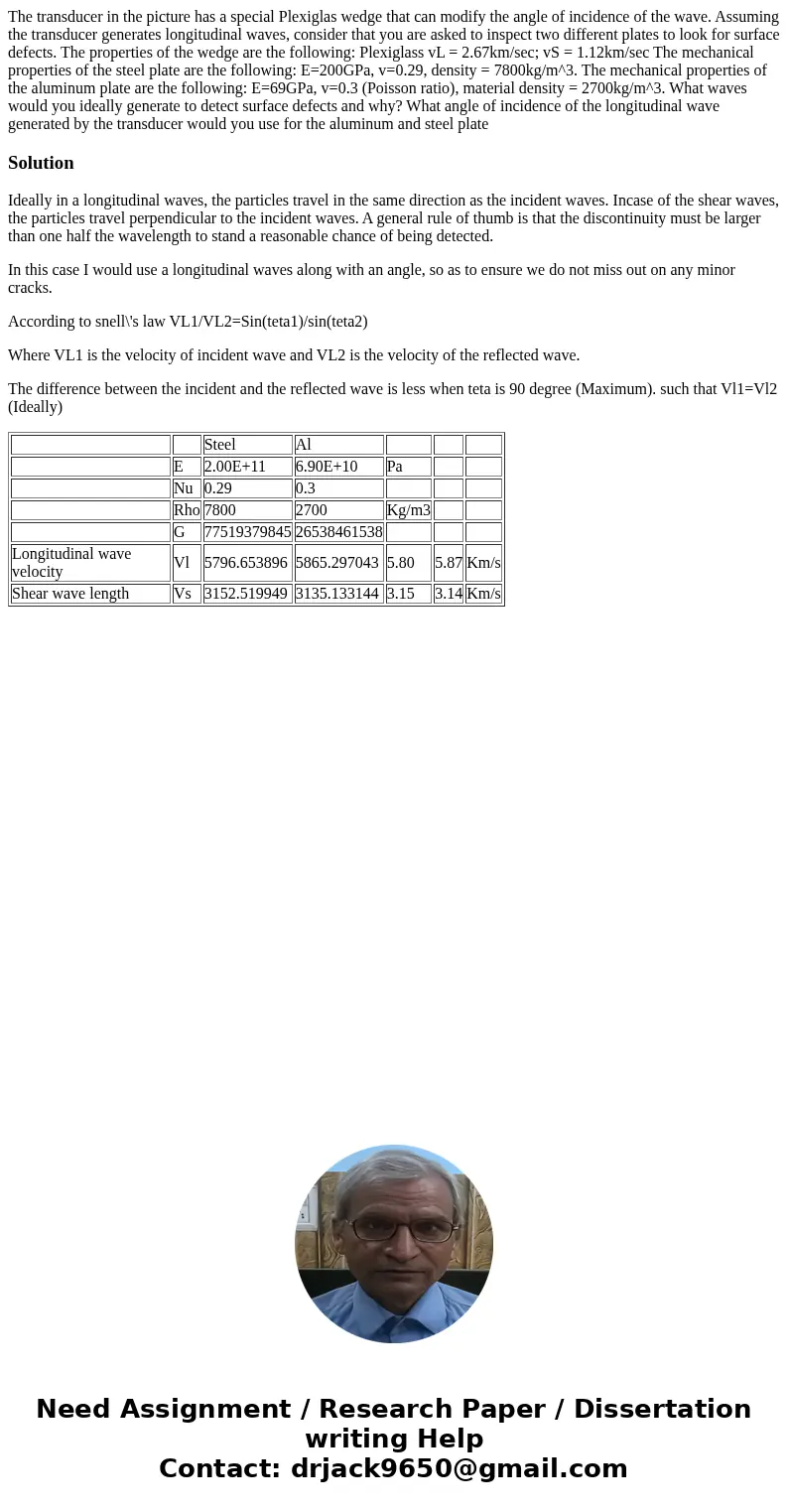

| Steel | Al | |||||

| E | 2.00E+11 | 6.90E+10 | Pa | |||

| Nu | 0.29 | 0.3 | ||||

| Rho | 7800 | 2700 | Kg/m3 | |||

| G | 77519379845 | 26538461538 | ||||

| Longitudinal wave velocity | Vl | 5796.653896 | 5865.297043 | 5.80 | 5.87 | Km/s |

| Shear wave length | Vs | 3152.519949 | 3135.133144 | 3.15 | 3.14 | Km/s |

Homework Sourse

Homework Sourse