A local car dealer wants to design its inventory system to m

Solution

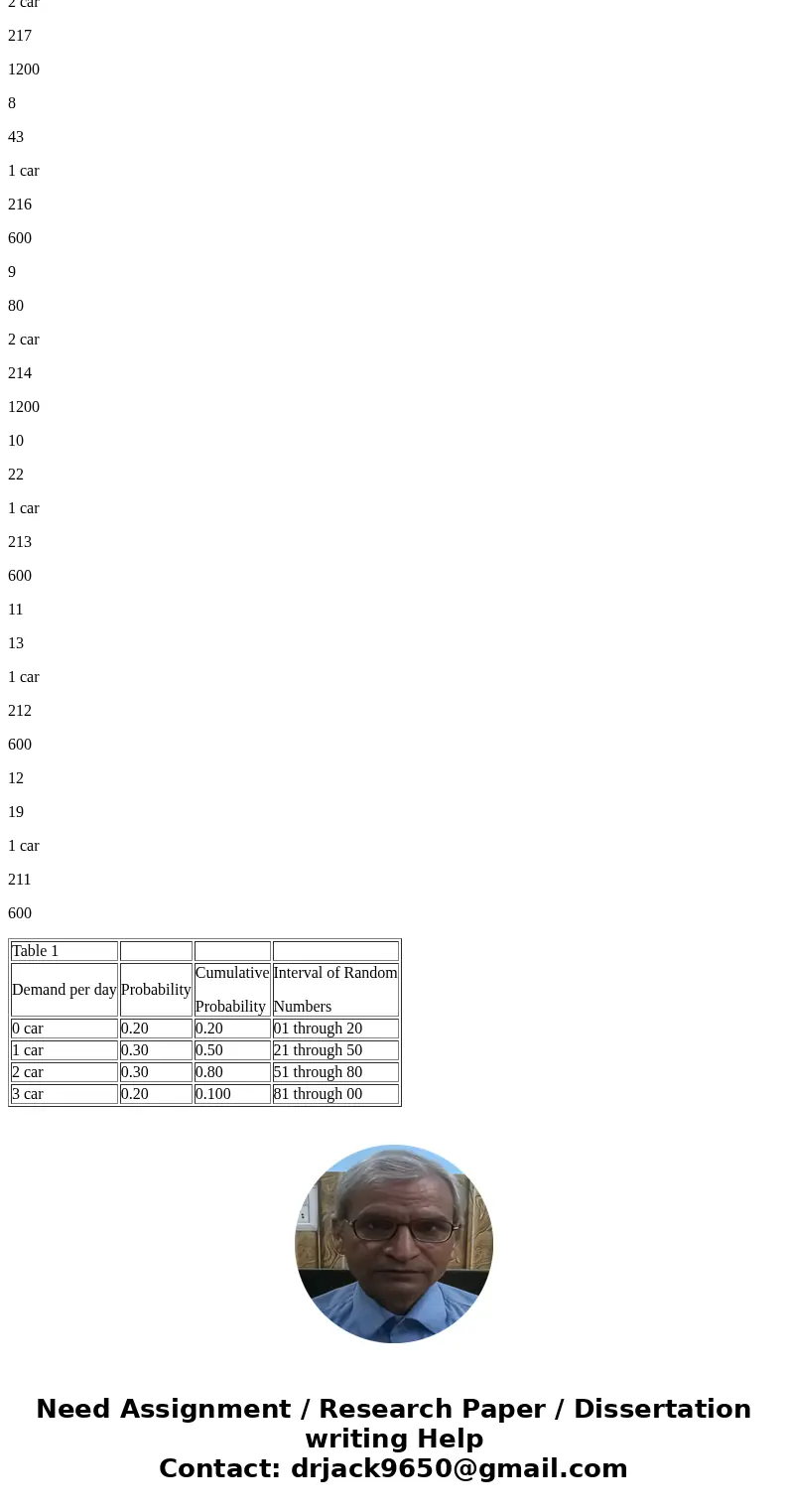

Assignment of Random numbers to daily demand per day:

Table 1

Demand per day

Probability

Cumulative

Probability

Interval of Random

Numbers

0 car

0.20

0.20

01 through 20

1 car

0.30

0.50

21 through 50

2 car

0.30

0.80

51 through 80

3 car

0.20

0.100

81 through 00

Assignment of Random numbers to days to receive an order:

Table 2

Days to receive an order

Probability

Cumulative

Probability

Interval of Random

Numbers

3 Days

0.40

0.40

01 through 40

5 Days

0.60

1.00

41 through 00

Day

Random Number

Demand per day

IOH

CLS

CPO

Random Number

Days to receive an order

1

03

0 car

225

0

0

2

80

2 car

223

1200

3

37

1 car

222

600

4

99

3 car

219

1800

5

19

0 car

6

11

0 car

7

68

2 car

217

1200

8

43

1 car

216

600

9

80

2 car

214

1200

10

22

1 car

213

600

11

13

1 car

212

600

12

19

1 car

211

600

| Table 1 | |||

| Demand per day | Probability | Cumulative Probability | Interval of Random Numbers |

| 0 car | 0.20 | 0.20 | 01 through 20 |

| 1 car | 0.30 | 0.50 | 21 through 50 |

| 2 car | 0.30 | 0.80 | 51 through 80 |

| 3 car | 0.20 | 0.100 | 81 through 00 |

Homework Sourse

Homework Sourse