Need help identifying strategies to adopt a timeline showing

Need help identifying strategies to adopt, a time-line showing the process to complete a manufacturing process – start to full production phase – and a 5-year financial projections from start of establishing the business, showing the amount of total FUNDS you need to establish and operate this business successfully, showing the best ROI to your management for this venture. And which activities can run parallel and which can not!

Assumptions:

Product: A/V Receiver for home entertainment /home theater use

Selling Price: $500 each

Cost of materials & Components: $100/unit

Direct Labor: 20 Persons, their salary is $5000/month

Full Production rate: 100 Units/day

Working days/Month: 25 days

O/H costs: 15%

Profit Rate: 25%

Rate of Growth for the company: 15% per year

As the production grows, the operating costs will grow with the same rate as well

The initial funding to purchase manufacturing equipment, furniture and other office facilities & remodeling of the leased buildings is = $350,000

List of Tasks (NOT in Proper order!):

Market Research 1 months $8,000

Plan for Business 1 months $12,000

Select Location, Land/Building for manufacturing 5 weeks $7000

Select Office Space for Business 2 weeks $3,000

Strategies/Objectives 1 week $5,000

Installing manufacturing equipment/machineries 2 months $10,000

Order additional equipment/tools/machineries 2 weeks $60,000

Order Office Equipment, Furniture, etc. 1 week $10,000

Design your Product 2 months $20,000

Approvals by Management for Design & Business Plan 2 weeks $8,000

Place order for all Components & Material for Production 3 weeks $15,000

Hire Production crew 3 weeks $10,000

Train the Production Crew 1 week $5,000

Hire Office Staff and setup Management team 2 weeks $8,000

Prepare Manuals for finished products & printing 3 months $15,000

Promotions & Advertising 3 months $85,000

Prepare marketing Materials 2 months $25,000

Select Dealerships 3 months $15,000

Testing the initial batch of Products for QC,

before the mass Production starts: 2 weeks $10,000

Solution

Since the company would engage in single product manufacturing ,here A/V receiver, home theater use. It is prident to use output costing technique as the company is going for mass production.Here element of cost is collated and identified & ascertained like direct materials,direct labour,direct expeses,prime cost, factory overheads,Administrative overhead,,selling & distribution overhead etc. Thus, the cost per unit can be derived as Total cost for the period / No. of units during the period. The statement of cost segregating the different heads and then arriving at profits can be used for projections

List of activities that can be carried out in seriatim with the corresponding time line is enumerated below:

Sl no

Activities

Time line

Remarks

1

Plan for Business

1 month

2

Strategies/Objectives

1 week

Can be done parallelly with Sl no 1

3

Market Research

1 month

Can run parallelly with Sl no 1

4

Select Location, Land/Building for manufacturing

5 weeks

Can run parallelly with Sl no 3

5

Select Office Space for Business

2 weeks

Can run parallelly with Sl no 3 &/or 4

6

Design your Product

2 months

7

Approvals by Management for Design & Business Plan

2 weeks

8

Installing manufacturing equipment/machineries

2 months

9

Select Dealerships

3 months

Can be done parallelly with sl no 8

10

Order Office Equipment, Furniture, etc.

1 week

Can be done parallelly with sl no 8 &/or 9

11

Hire Production crew

3 weeks

Can be done parallelly with sl no 8 &/or 9

12

Train the Production Crew

1 week

13

Hire Office Staff and setup Management team

2 weeks

14

Prepare Manuals for finished products & printing

3 months

15

Testing the initial batch of Products for QC,

before the mass Production starts

2 weeks

16

Prepare marketing Materials

2 months

17

Promotions & Advertising

3 months

18

Place order for all Components & Material for Production

3 weeks

19

Order additional equipment/tools/machineries

2 weeks

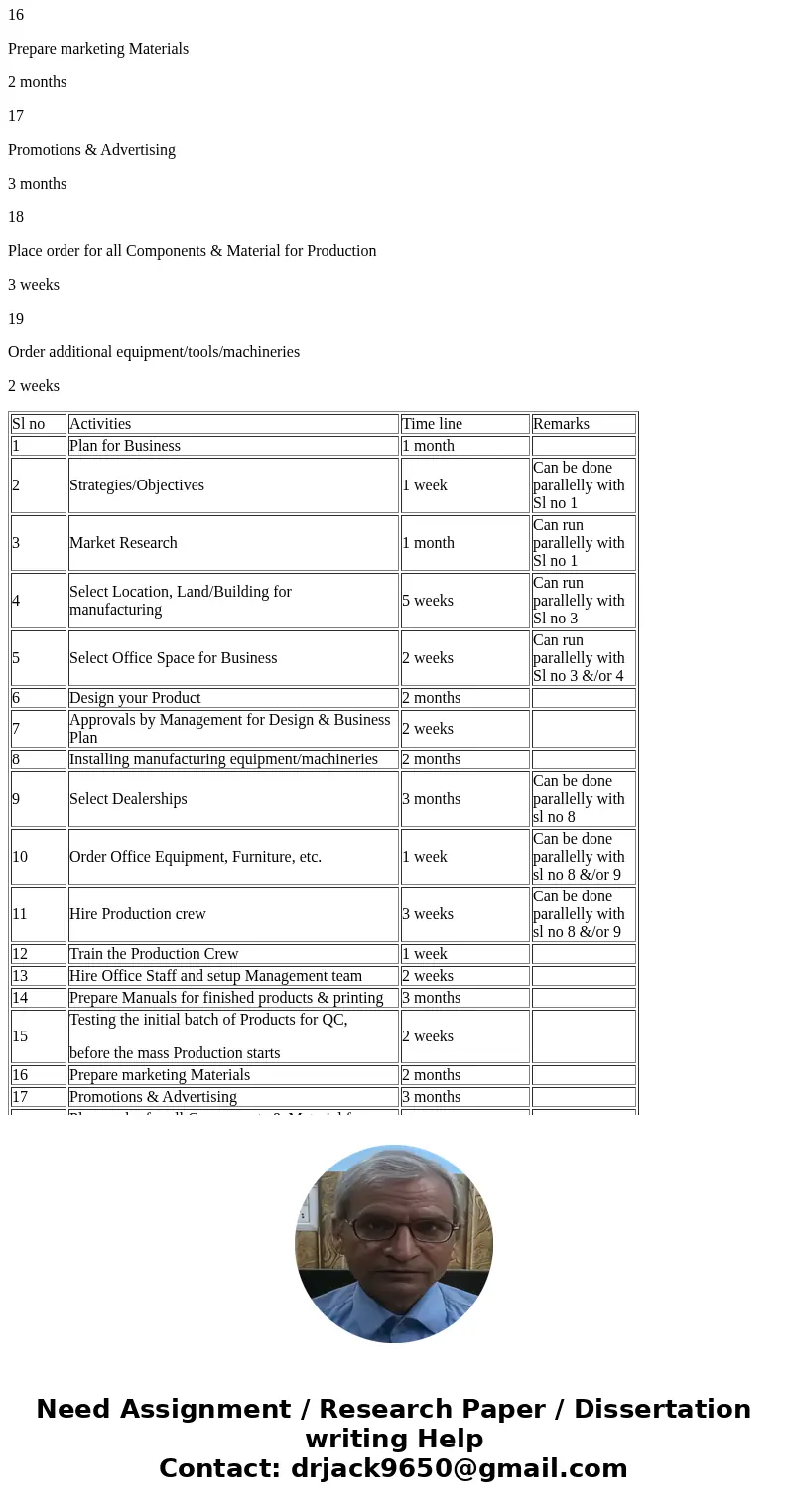

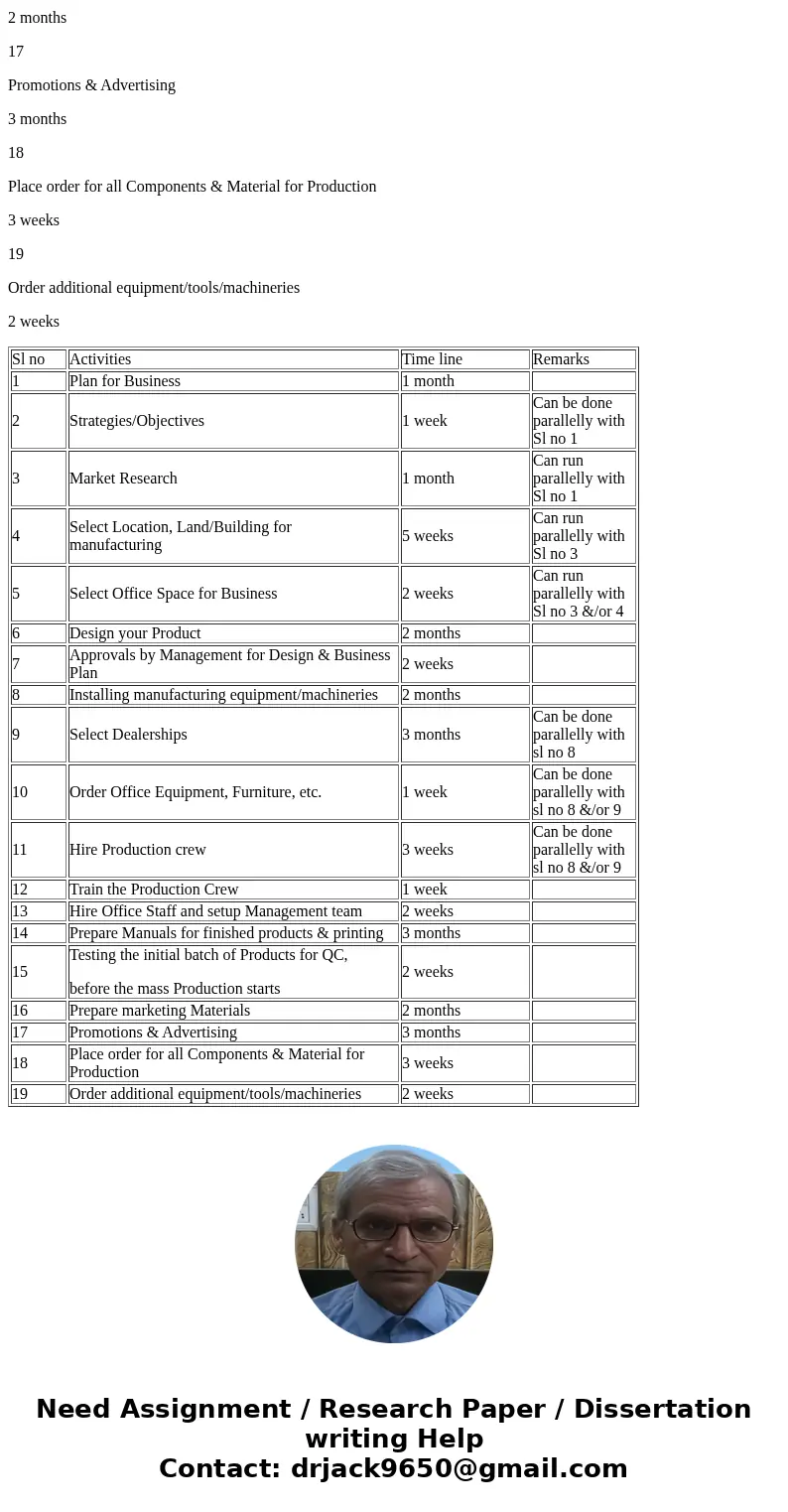

| Sl no | Activities | Time line | Remarks |

| 1 | Plan for Business | 1 month | |

| 2 | Strategies/Objectives | 1 week | Can be done parallelly with Sl no 1 |

| 3 | Market Research | 1 month | Can run parallelly with Sl no 1 |

| 4 | Select Location, Land/Building for manufacturing | 5 weeks | Can run parallelly with Sl no 3 |

| 5 | Select Office Space for Business | 2 weeks | Can run parallelly with Sl no 3 &/or 4 |

| 6 | Design your Product | 2 months | |

| 7 | Approvals by Management for Design & Business Plan | 2 weeks | |

| 8 | Installing manufacturing equipment/machineries | 2 months | |

| 9 | Select Dealerships | 3 months | Can be done parallelly with sl no 8 |

| 10 | Order Office Equipment, Furniture, etc. | 1 week | Can be done parallelly with sl no 8 &/or 9 |

| 11 | Hire Production crew | 3 weeks | Can be done parallelly with sl no 8 &/or 9 |

| 12 | Train the Production Crew | 1 week | |

| 13 | Hire Office Staff and setup Management team | 2 weeks | |

| 14 | Prepare Manuals for finished products & printing | 3 months | |

| 15 | Testing the initial batch of Products for QC, before the mass Production starts | 2 weeks | |

| 16 | Prepare marketing Materials | 2 months | |

| 17 | Promotions & Advertising | 3 months | |

| 18 | Place order for all Components & Material for Production | 3 weeks | |

| 19 | Order additional equipment/tools/machineries | 2 weeks |

Homework Sourse

Homework Sourse