Waymire Ltd manufactures two products and currently allocate

Waymire Ltd. manufactures two products and currently allocates overhead based on direct labour hours. For the coming year, the company is considering changing to an activity based costing system by allocating overhead based on 3 activities. The estimated amount of overhead traceable to the 3 activities for the coming year are given below:

Activity

Cost driver

Cost

Product 1

Product 2

Purchase orders

# of orders

$840347

312

579

Maintenance

Machine hours

$456759

18555

19721

Inspection

# of inspections

$718649

1526

2200

Total estimated direct labour hours for the coming year are 33444 hours for Product 1 and 84234 hours for Product 2.

What is the difference between total overhead allocated to Product 2 using activity based costing versus traditional costing? Note: a negative number indicates less total overhead allocated using activity based costing.

| Activity | Cost driver | Cost | Product 1 | Product 2 |

| Purchase orders | # of orders | $840347 | 312 | 579 |

| Maintenance | Machine hours | $456759 | 18555 | 19721 |

| Inspection | # of inspections | $718649 | 1526 | 2200 |

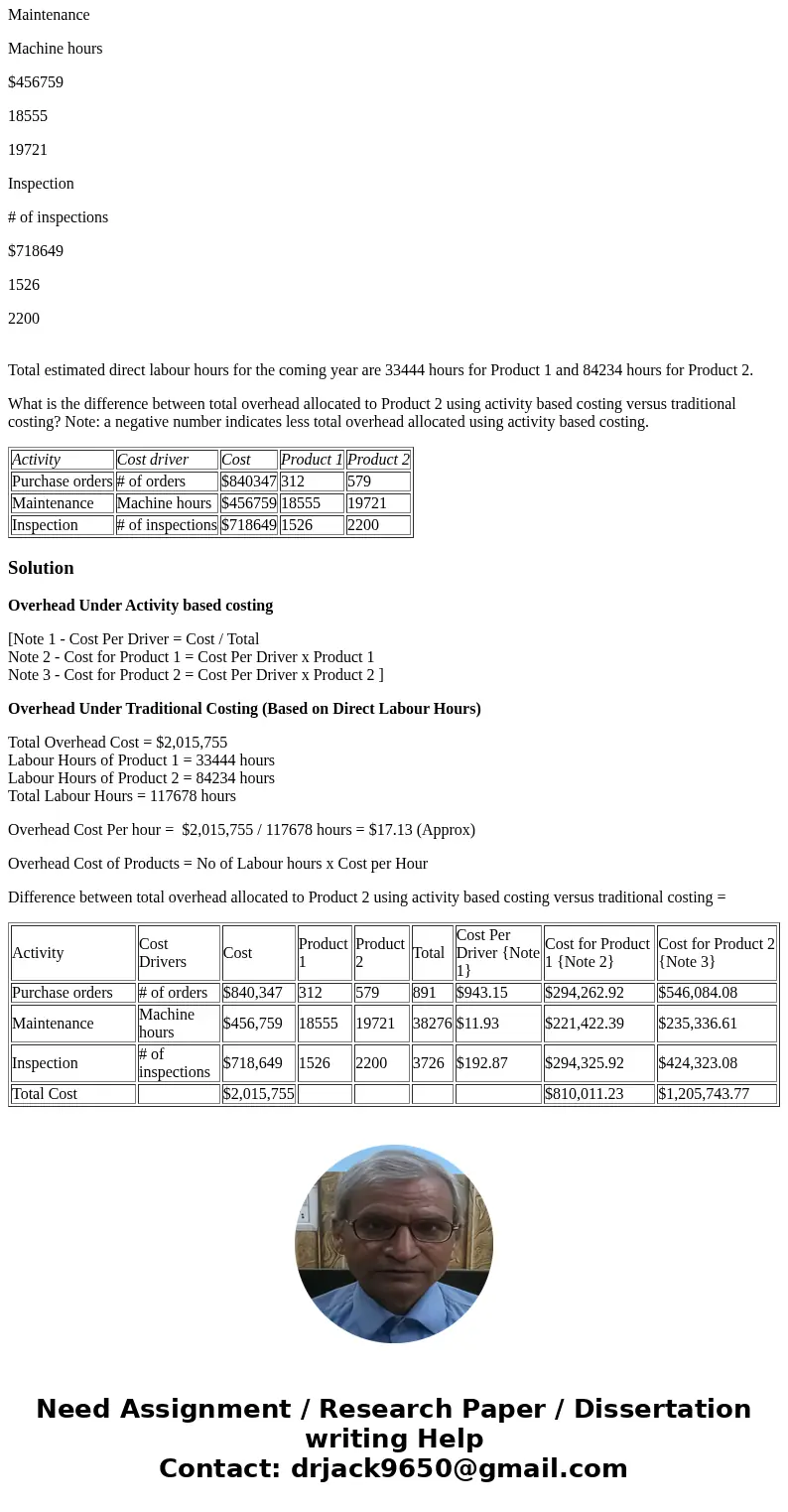

Solution

Overhead Under Activity based costing

[Note 1 - Cost Per Driver = Cost / Total

Note 2 - Cost for Product 1 = Cost Per Driver x Product 1

Note 3 - Cost for Product 2 = Cost Per Driver x Product 2 ]

Overhead Under Traditional Costing (Based on Direct Labour Hours)

Total Overhead Cost = $2,015,755

Labour Hours of Product 1 = 33444 hours

Labour Hours of Product 2 = 84234 hours

Total Labour Hours = 117678 hours

Overhead Cost Per hour = $2,015,755 / 117678 hours = $17.13 (Approx)

Overhead Cost of Products = No of Labour hours x Cost per Hour

Difference between total overhead allocated to Product 2 using activity based costing versus traditional costing =

| Activity | Cost Drivers | Cost | Product 1 | Product 2 | Total | Cost Per Driver {Note 1} | Cost for Product 1 {Note 2} | Cost for Product 2 {Note 3} |

| Purchase orders | # of orders | $840,347 | 312 | 579 | 891 | $943.15 | $294,262.92 | $546,084.08 |

| Maintenance | Machine hours | $456,759 | 18555 | 19721 | 38276 | $11.93 | $221,422.39 | $235,336.61 |

| Inspection | # of inspections | $718,649 | 1526 | 2200 | 3726 | $192.87 | $294,325.92 | $424,323.08 |

| Total Cost | $2,015,755 | $810,011.23 | $1,205,743.77 |

Homework Sourse

Homework Sourse