Your task is to provide design specifications for spherical

Solution

For A-36 Steel

Yield Strength = 36 ksi

t1 = 1/16 in = 0.0625 in

t2 = t1+0.0625 = 0.125

t3 = t2+0.0625 = 0.1876

t4 = t3+0.0625 = 0.25

t8 = t7+0.0625 = 0.5

As per distortion energy theory

This states that failure occurs when the von Mises stress e in the component being designed equals the von Mises stress e in a uniaxial tensile test at the yield stress:

e = SY/FS

FS=2

So e = 36 ksi/2 = 18 ksi

This is the allowable stress in thin pressure vessel.

e = [P*r] / [2*t]

Pmax = [e *2*t] / r = 18*2*0.0625/r = 2.25 /r ksi = [2250 /r] psi

When pressure vessels have walls that are thin in comparison to their radii and length. In the case of thin walled pressure vessels of spherical shape the ratio of radius r to wall thickness t is greater than 10. A sphere is the theoretical ideal shape for a vessel that resists internal pressure.

r > 10*t

Let assume that r = 0.8 in [r = inner diameter ]

So Pmax = 2812.5 psi

This is a approximate value and user can replace this with actual no.

Volume of sphere = 4/3 [pi* r^3]

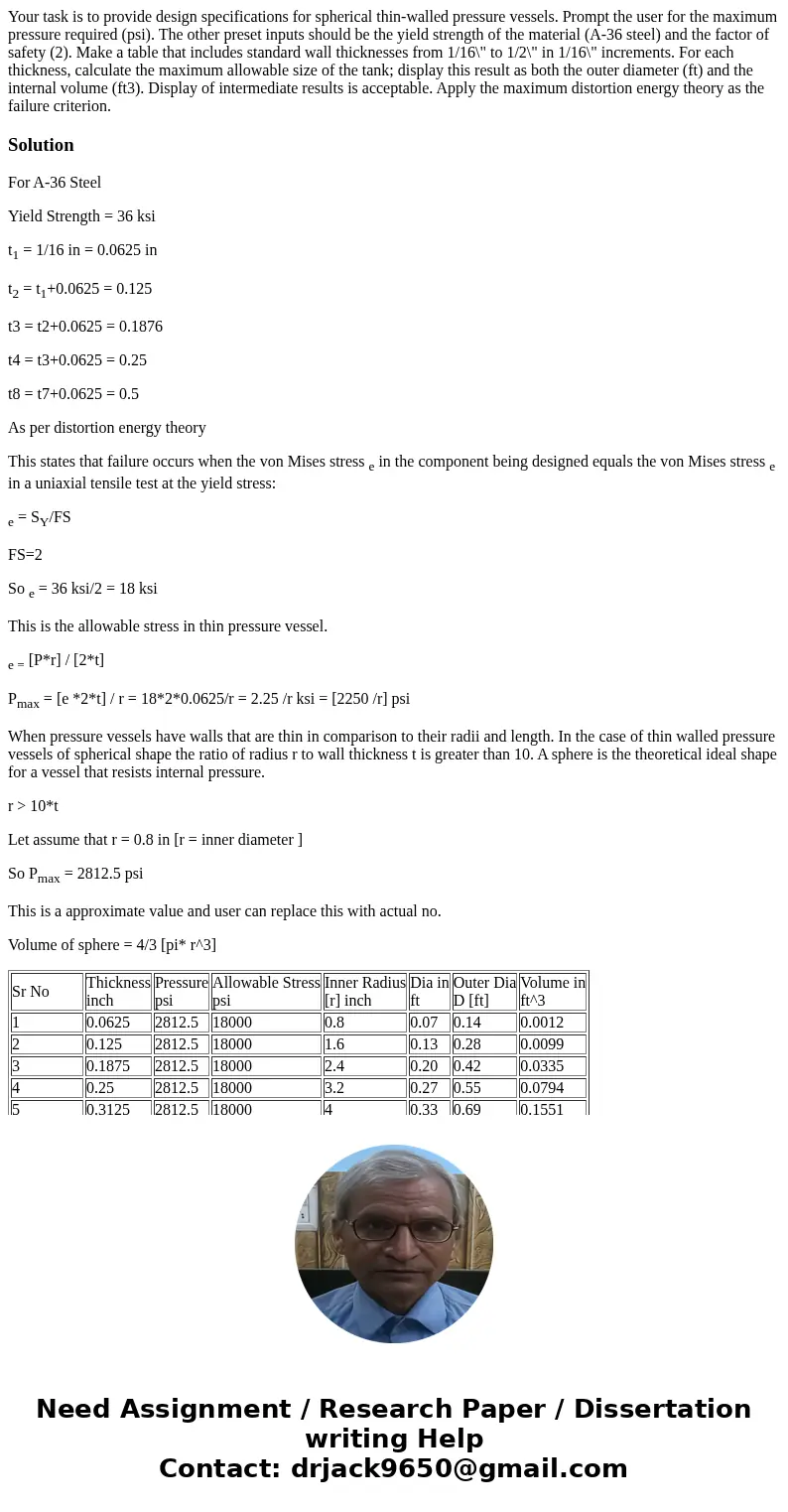

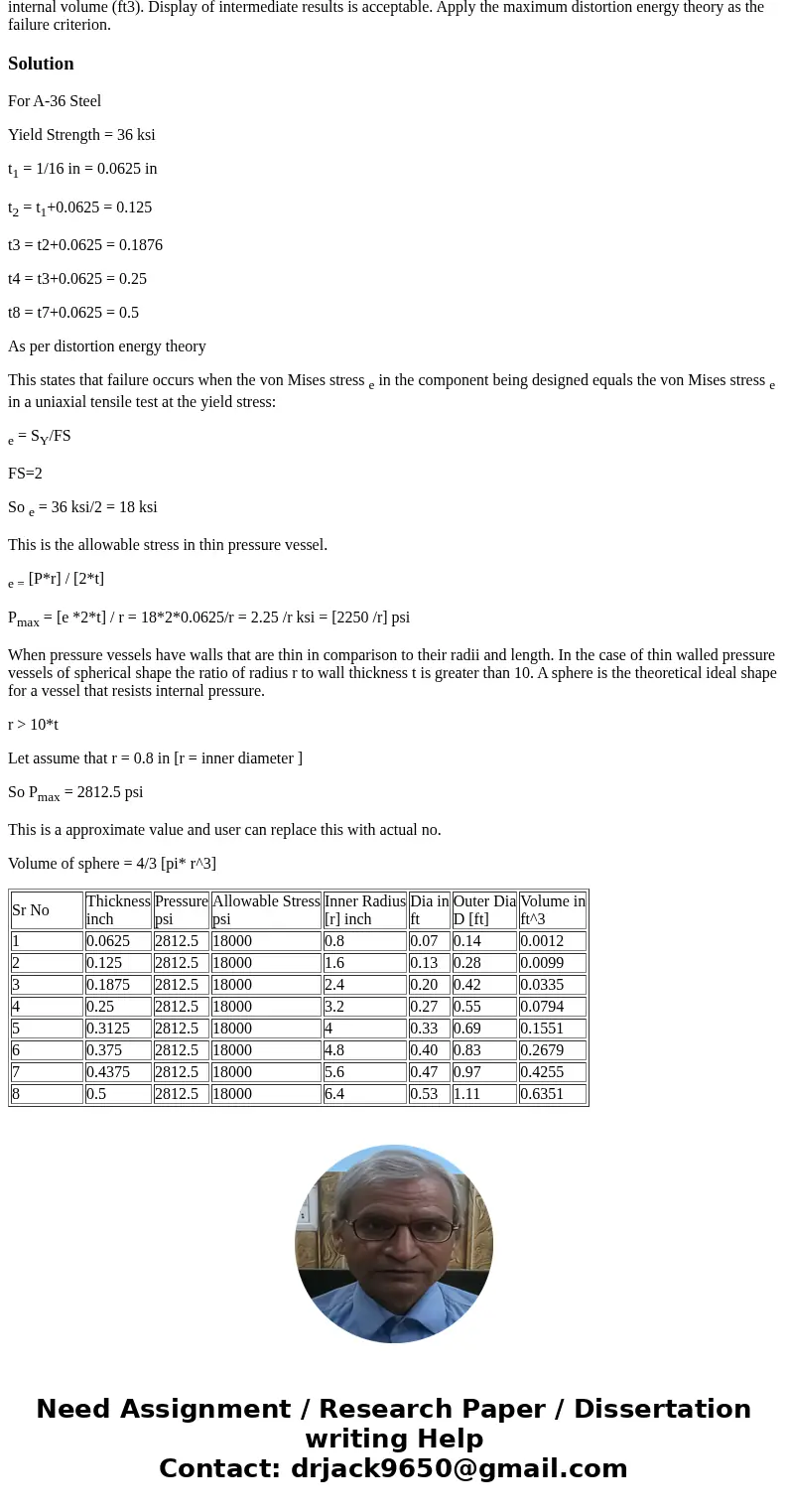

| Sr No | Thickness inch | Pressure psi | Allowable Stress psi | Inner Radius [r] inch | Dia in ft | Outer Dia D [ft] | Volume in ft^3 |

| 1 | 0.0625 | 2812.5 | 18000 | 0.8 | 0.07 | 0.14 | 0.0012 |

| 2 | 0.125 | 2812.5 | 18000 | 1.6 | 0.13 | 0.28 | 0.0099 |

| 3 | 0.1875 | 2812.5 | 18000 | 2.4 | 0.20 | 0.42 | 0.0335 |

| 4 | 0.25 | 2812.5 | 18000 | 3.2 | 0.27 | 0.55 | 0.0794 |

| 5 | 0.3125 | 2812.5 | 18000 | 4 | 0.33 | 0.69 | 0.1551 |

| 6 | 0.375 | 2812.5 | 18000 | 4.8 | 0.40 | 0.83 | 0.2679 |

| 7 | 0.4375 | 2812.5 | 18000 | 5.6 | 0.47 | 0.97 | 0.4255 |

| 8 | 0.5 | 2812.5 | 18000 | 6.4 | 0.53 | 1.11 | 0.6351 |

Homework Sourse

Homework Sourse