The following are quality control data for a manufacturing p

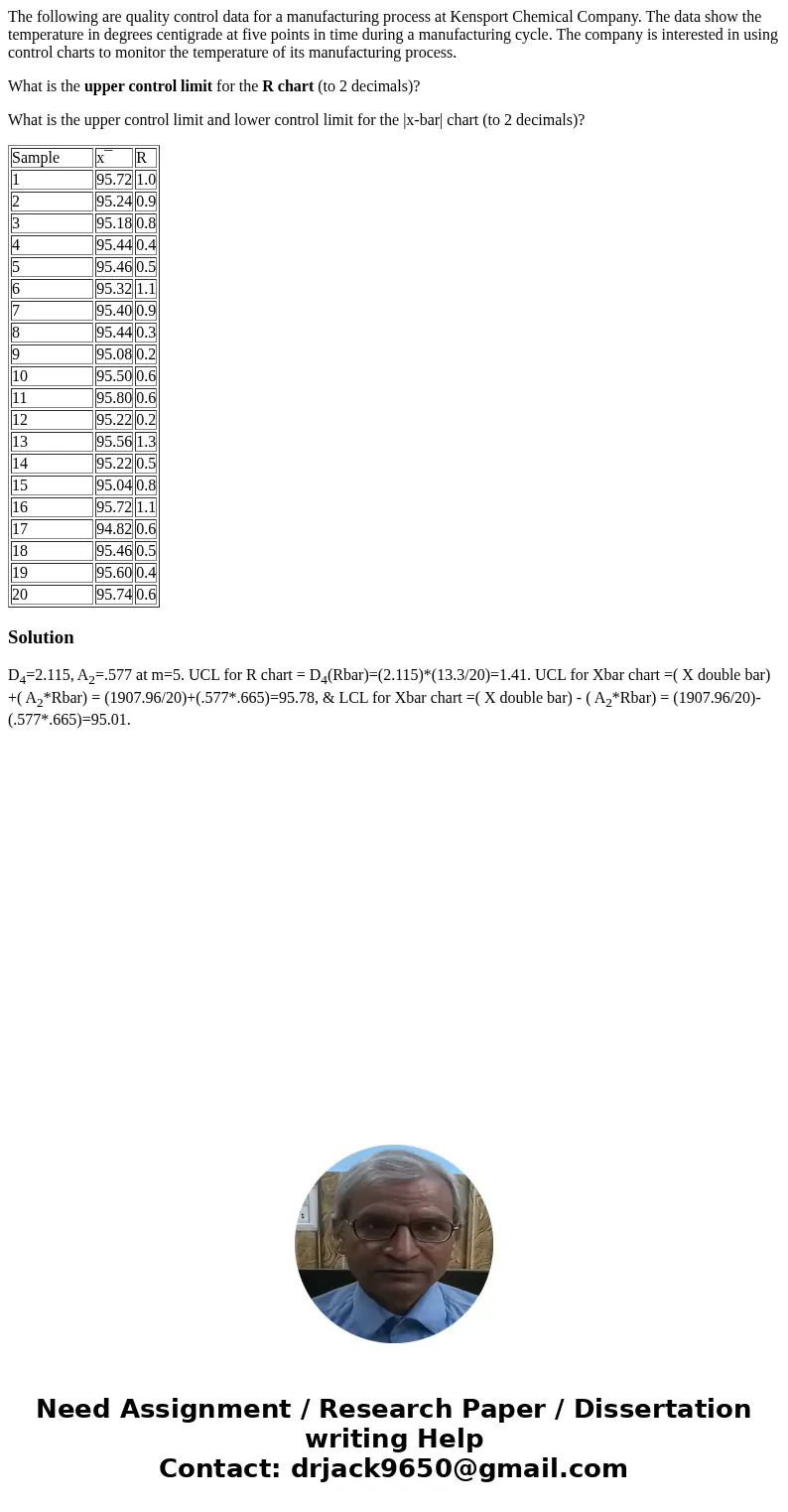

The following are quality control data for a manufacturing process at Kensport Chemical Company. The data show the temperature in degrees centigrade at five points in time during a manufacturing cycle. The company is interested in using control charts to monitor the temperature of its manufacturing process.

What is the upper control limit for the R chart (to 2 decimals)?

What is the upper control limit and lower control limit for the |x-bar| chart (to 2 decimals)?

| Sample | x¯ | R |

| 1 | 95.72 | 1.0 |

| 2 | 95.24 | 0.9 |

| 3 | 95.18 | 0.8 |

| 4 | 95.44 | 0.4 |

| 5 | 95.46 | 0.5 |

| 6 | 95.32 | 1.1 |

| 7 | 95.40 | 0.9 |

| 8 | 95.44 | 0.3 |

| 9 | 95.08 | 0.2 |

| 10 | 95.50 | 0.6 |

| 11 | 95.80 | 0.6 |

| 12 | 95.22 | 0.2 |

| 13 | 95.56 | 1.3 |

| 14 | 95.22 | 0.5 |

| 15 | 95.04 | 0.8 |

| 16 | 95.72 | 1.1 |

| 17 | 94.82 | 0.6 |

| 18 | 95.46 | 0.5 |

| 19 | 95.60 | 0.4 |

| 20 | 95.74 | 0.6 |

Solution

D4=2.115, A2=.577 at m=5. UCL for R chart = D4(Rbar)=(2.115)*(13.3/20)=1.41. UCL for Xbar chart =( X double bar) +( A2*Rbar) = (1907.96/20)+(.577*.665)=95.78, & LCL for Xbar chart =( X double bar) - ( A2*Rbar) = (1907.96/20)-(.577*.665)=95.01.

Homework Sourse

Homework Sourse