110 Search E45 Assigning Costs Using Activity Proportions IL

Solution

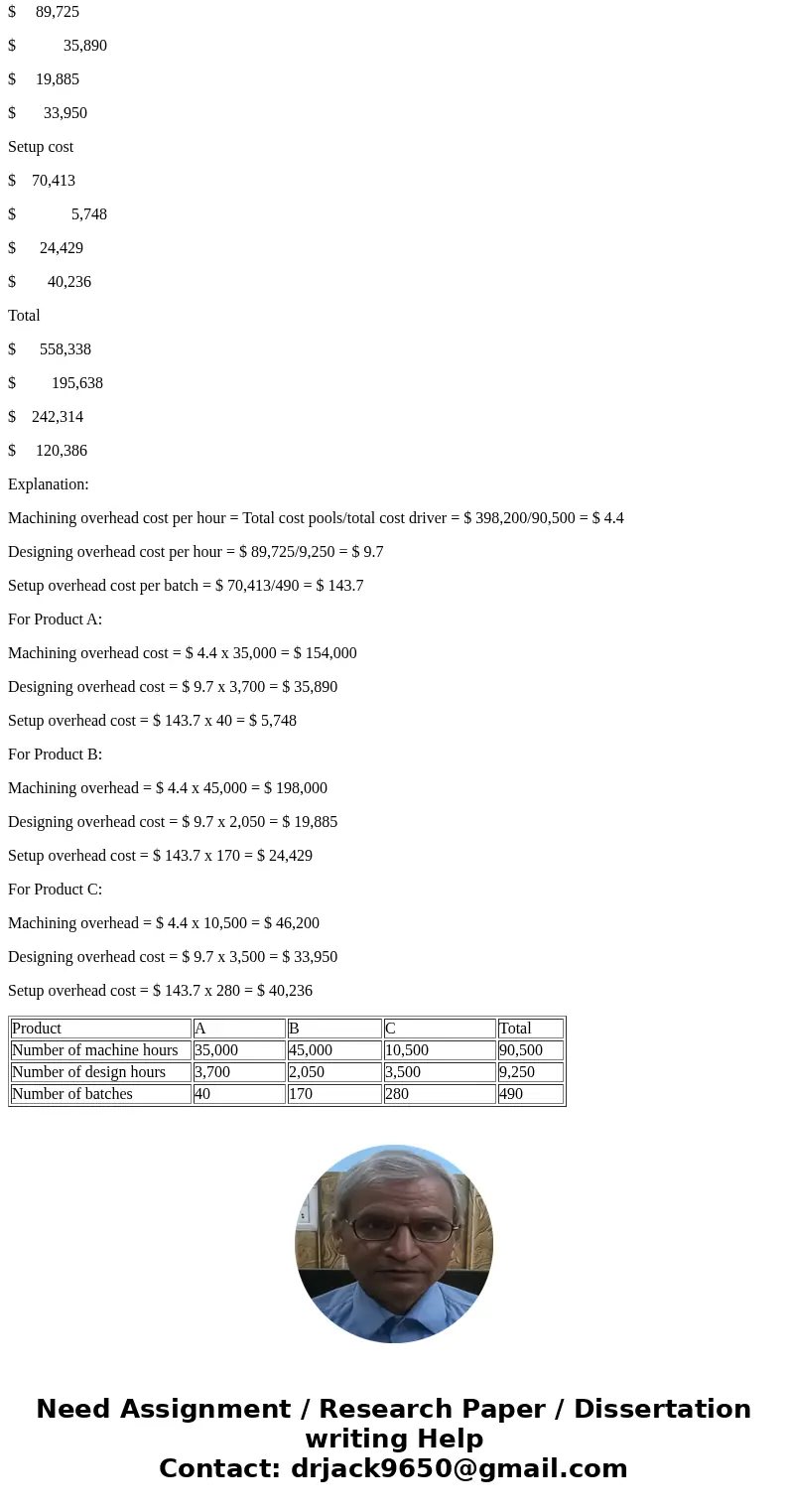

Product

A

B

C

Total

Number of machine hours

35,000

45,000

10,500

90,500

Number of design hours

3,700

2,050

3,500

9,250

Number of batches

40

170

280

490

Activity Cost Pools

Total cost of pools

Product A

Product B

Product C

Machining

$ 398,200

$ 154,000

$ 198,000

$ 46,200

Designing cost

$ 89,725

$ 35,890

$ 19,885

$ 33,950

Setup cost

$ 70,413

$ 5,748

$ 24,429

$ 40,236

Total

$ 558,338

$ 195,638

$ 242,314

$ 120,386

Explanation:

Machining overhead cost per hour = Total cost pools/total cost driver = $ 398,200/90,500 = $ 4.4

Designing overhead cost per hour = $ 89,725/9,250 = $ 9.7

Setup overhead cost per batch = $ 70,413/490 = $ 143.7

For Product A:

Machining overhead cost = $ 4.4 x 35,000 = $ 154,000

Designing overhead cost = $ 9.7 x 3,700 = $ 35,890

Setup overhead cost = $ 143.7 x 40 = $ 5,748

For Product B:

Machining overhead = $ 4.4 x 45,000 = $ 198,000

Designing overhead cost = $ 9.7 x 2,050 = $ 19,885

Setup overhead cost = $ 143.7 x 170 = $ 24,429

For Product C:

Machining overhead = $ 4.4 x 10,500 = $ 46,200

Designing overhead cost = $ 9.7 x 3,500 = $ 33,950

Setup overhead cost = $ 143.7 x 280 = $ 40,236

| Product | A | B | C | Total |

| Number of machine hours | 35,000 | 45,000 | 10,500 | 90,500 |

| Number of design hours | 3,700 | 2,050 | 3,500 | 9,250 |

| Number of batches | 40 | 170 | 280 | 490 |

Homework Sourse

Homework Sourse